AEI Compounds Ltd.: Introducing new HFFR Ceramifiable technology for fire survival/fire safety cables

AEI Compounds Ltd.: Introducing new HFFR Ceramifiable technology for fire survival/fire safety cables

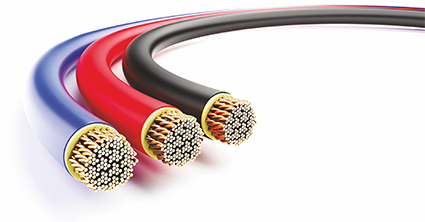

AEI Compounds Ltd. UK, a leading manufacturer of cable and wire compounds, is pleased to introduce athermoplastic Halogen Free Flame Retardant (HFFR), TP0851. This is a new ceramifiable HFFR sheathing compound for cables built to preserve circuit integrity in fire situations. TP 0851 has been used successfully in emergency alarm, communication and lighting circuits. Other fire-survival cable applications are now being tested using the ceramifiable HFFR compound technology developed at AEI.

The ceramifiable sheathing material forms a strong char during burning, providing enhanced cable fire protection and enables the cable to function in serious fire situations. When TP-0851 is used with silicone rubber insulated cores the most onerous fire performance specifications can be satisfied. Traditional fire survival cable constructions using Mica tapes may be eliminated. The use of TP 0851 for cable sheathing in certain cable constructions allows improved cable production efficiency and faster cable termination performance.

TP0851-sheathed cables have met the fire test requirements of BS EN 50200 for PH 120 and the enhanced BS 8434-2 with a 930°C flame and water spray with aluminium laminate tape screens.

New compound SX-0612S is a silane crosslinkable HFFR insulation material complying with BS7211 & BS EN 50525-3-41:2011. SX-0612S processes at high production speeds; it is also highly resistant to pre cure in extruders but is capable of crosslinking in ambient conditions. The company also announced it will be showcasing the well-respected Pexidan UL-qualified range of insulation grades from Saco Polymers at the show.

Visit AEI Compounds at

Hall 11 / Booth D46

……………………………………………………………………………………………………………………………………………

Agir Technologies: Offering most complex and complete range of tools

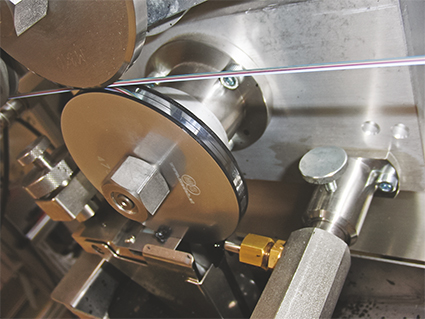

Agir Technologies (Mouton-Rivom), the oldest company in the world producing tungsten carbide tools for metal forming, has developed for five years a complete and performing range of automatic machines that enable the user to repair tungsten carbide drawing dies with precision (automatic control) and in very short times.

The company also produces three types of precise grinding machines with chuck from 80 to 160 mm as well as polishing lathes. It also manufactures wire shaving heads and machines to remove the impurities or corrosion for a better surface finish of the wire.

Visit Agir Technologies at

Hall 10 / Booth G56

……………………………………………………………………………………………………………………………………………

Chengdu Centran Industrial Co., Ltd

Chengdu Centran Industrial Co., Ltd is a leading global supplier of excellent raw materials to cable and wire industry. It is one of the biggest manufacturers of water-blocking tape, waterswellabe yarn and polyester yarn, marking tape, flame-retardant tape, etc., in China.

It will showcase its latest new products, such as E-glass water-blocking yarn and semi-conductive copper wire water-blocking tape.

Visit Chngdu Centran at

Hall 9 / Booth F75

……………………………………………………………………………………………………………………………………………

Candor Sweden AB: A unique partner for surface treatment of wire

Candor Sweden AB: A unique partner for surface treatment of wire

Candor was founded in 1946 and is specialised in cleaning and plating plants for wire and a supplier of chemicals for various applications.

The combination of its know-how in chemical processes and its advanced equipment for cleaning and plating of wire makes it unique on the market. It knows how to clean and metal coat your wire.

Candor supplies both single- and multi strand systems for ferrous and non-ferrous materials, and all plants are tailor made after customer request.

At WIRE 2014, Candor will introduce the Copperjet plant, a newly developed, high-speed and copper-coating plant for welding wires at high wire speeds with best possible quality.

A modular design makes it possible to satisfy a wide range of applications according to customer request.

Visit Candor Sweden AB at

Hall 10 / Booth B72

……………………………………………………………………………………………………………………………………………

Construcciones Mecánicas Caballé, S.A.: Specialists on Stranding Machines since 1944

Construcciones Mecánicas Caballé, S.A.: Specialists on Stranding Machines since 1944

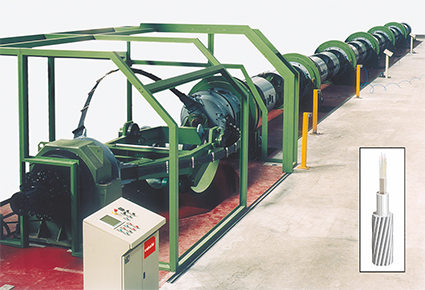

With over 70 years of experience in the design and manufacture of rotating machinery for the production of power and telecommunication cables as well as steel ropes, the Spanish company C.M. Caballé provides the cable industry with a wide array of stranding, twinning, bunching and cabling machinery. The firm is constantly developing new, high quality equipment to meet the ever-changing needs of wire and cable industry.

The company’s portfolio includes the following:

• Power cables: double twist stranders, rigid stranders, drum twisters, single twist stranders, bow skip stranders, tubular stranders, planetary stranders and SZ stranders.

• Telecom and LAN cables: double twist pairing-quadding machines, single twist cabling lines, group twinners, drum twisters, shielding-jelly filling-sheathing lines, SZ stranders.

• Steel ropes: double twist stranders, tubular stranders, planetary stranders, bow skip stranders.

• Ancillary equipment: pay-offs, take-ups, capstans, caterpillars, taping machines, binders.

At Wire Düsseldorf 2014, the company will showcase a new “bullhead” tubular strander for 32 DIN 500 reels and one DIN 1600 reel for the core for the production of OPGW cables and armouring of optical cables. This machine is presented as an alternative to the classical planetary or tubular stranders. Caballe has solved the drawbacks of both machines by adding a “Bull-Head-Feeder”. This is a system integrated at the end of the tubular strander that consists of a big pay-off with some bows that turn around it and convey the wires coming from the tubular to the closing point.

With this system the central tube with the fibre optics inside is paid-off completely straight and no twist is given to it, so the quality is the same as with a planetary strander but with a much higher stranding speed. The productivity of this machine is five times higher than that of a planetary strander.

Visit CM Caballe at

Hall 11 / Booth G65

……………………………………………………………………………………………………………………………………………

Clifford Welding Systems: Company with a vision to produce top quality affordable machinery for the ferrous wire industry

The company will exhibit in the wire show and will have its full sales team and agents from around the world to discuss its product lines consisting of reinforced mesh welders, fine mesh welders, fence mesh welders, grating welders, rolling lines and straighten and cut-to-length lines.

Visit Clifford Welding Systems at

Hall 16 / Booth B28

……………………………………………………………………………………………………………………………………………

DELISI: Automatic wire straightening and cutting machines provider

DELISI: Automatic wire straightening and cutting machines provider

DELISI manufactures and sells automatic wire straightening and cutting machines for diameters from 1 up to 22 mm, for smooth and ribbed wire.

Its new model HS22H with hydraulic and flying shear cut, for wires from 10 to 22 mm, is suitable for smooth wires and, with the addition of a special device, for really short pieces. This model can also work on ribbed wire. The HS22H machine has four couples of feeding rolls and rapid change of diameter. Its feed speed ranges from 30 to 150 m/min. Reduced wire twisting, increased production and reduced noise are its other features.

Visit Delisi at

Hall 10 / Booth H24

……………………………………………………………………………………………………………………………………………

DEM Wire Rolling Technology designs, manufactures, constructs and commissions competitive plants, equipment and automation systems for the wire industry. DEM delivers worldwide solutions for cold material transformation in the wire field, such as Profile Wire Rolling, Flat Wire Rolling, Construction Wire Rolling, Plain Wire Rolling and Welding Wire Rolling. DEM stand at the show can be used as a platform to access information about the following technology areas:

• Non-ferrous strips for use in power systems.

• Profile forming at near-zero tolerance, yet rolled fast. Precision Rolling Stand on show.

• The Perfect Coiler on show.

• Cold rolling uses heat for better profiles.

• Reinforcing steel in bars as fast as in coils – now true!

• Microcassettes: changing your drawing process to a rolling one. Units on show.

• Cassettes for rebar. Bull Block on show.

Visit DEM at

Hall 11 / Booth H41

……………………………………………………………………………………………………………………………………………

Die Quip: you get more than just a machine

Die Quip: you get more than just a machine

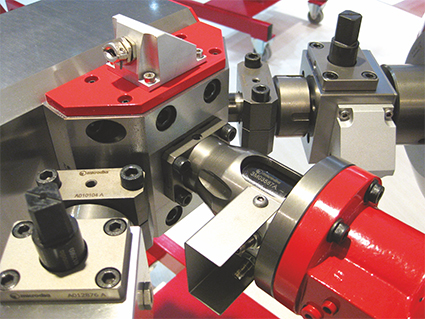

The goal of making more wire per die is easily reached with a Die Quip die finishing machine. As a global manufacturing leader, the company has established a line of machines to grind, polish and size dies in a quick, efficient, accurate process eliminating operator error and guesswork. Better dies pull more wire and cause less production problems so it has designed stand-alone machines for finishing dies in all sizes, and for larger production runs it builds work cells to keep maximum efficiency and eliminate downtime from size changeovers. Its approach to a modern die shop brings huge benefits to the whole production process by implementing a workflow system that sets procedures and incorporates training to maximise each machine’s capabilities.

The company has designed many extensive training options and onsite consultations that teach operators how to use its equipment, choose diamond tooling for maximum results and different methods of making dies. Its technicians will spend time in your facility designing a programme customised to meet your production needs and provide reference materials such as its exclusive Die Training Handbook.

Visit Die Quip at

Hall 09 / Booth D06-01

……………………………………………………………………………………………………………………………………………

Eder Engineering: Advanced drawing die-tools, die processing technology and equipment

Eder Engineering: Advanced drawing die-tools, die processing technology and equipment

Offering innovative and high value added concepts with over 65 years of expertise in the field of reconditioning die working equipment, EDER is sustaining and developing its distinctive leading position across the globe and is showcasing its various technologically leading equipment.

Here are some examples of EDER machines that will be showcased at the show:

• “ETC-1/HF” Efficient tungsten carbide die grinding and polishing equipment with a very large work-range – from 0.10 to 20 mm dia.

• Particularly for refurbishing of the continuously growing quantity of PCD dies in use, a unique ultrasonic machine, model “USP-TWIN”, with two workstations has been developed, which can efficiently work all die-sizes in a large range – from 0.05 to 8.0 mm dia.

• “HGM-21” – for sizing and polishing the cylindrical bearing of a mid to larger quantity of ND/PCD dies, is an efficient and versatile wire-type calibration machine; also offering two individually PLC controlled workstations and a uniquely large work-range – from 0.05 to 10 mm dia.

Visit Eder Engineering at

Hall 10 / Booth A40-02

……………………………………………………………………………………………………………………………………………

ENKOTEC: A dedicated partner for your nail manufacturing needs

ENKOTEC: A dedicated partner for your nail manufacturing needs

ENKOTEC will present its brand-new paper collator, the ENKOllator type CTS01, which has been designed for making collated sticks of nails with three head types, full round head, D-head and offset head with a speed of up to 2,300 nails per minute. The collator has a very regular footprint, with all components integrated, and allows easy access to machine maintenance by removable front panels. The collation angle is obtained by easy adjustment at the spindle insertion system. The machine features a new type of stick cutting system with minimal wear and almost no adjustment.

Following a recent agreement with BAUSSMANN Collated Fasteners GmbH, giving ENKOTEC exclusive rights to sell and service BAUSSMANN’s wire coil collator worldwide, ENKOTEC and BAUSSMANN will jointly exhibit a high-speed in-line nail manufacturing line.

The exhibit will include the ENKOllator, type CWC01, with packaging machine, type PCC01, both engineered and built by Baussmann. Using automatic cutter and coiling units, the wire coil collator can produce bright and electro galvanised wire welded coil nails with smooth shank, ring shank, screw shank and spiral shank.

The in-line system will also feature the brand-new model within the high-volume ENKOnail+ series of rotary nail machines, theNP02, producing 2,500 nails per minute of diameter ø1,8 to 2,5 mm and lengths as low as 28 to 57 mm.

The NP02 machine will be set up with an ENKOroll thread-rolling machine, type TA01, designed for making screw shank or annular nail profiles.

Visitors to ENKOTEC’s booth will also see the latest ENKOnail machine, type MM01, intended for small and midsize capacity needs, which will be running together with ENKOTEC’s movable packaging machine, ENKOpacktype NCP02.

Visit ENKOTEC at

Hall 15 / Booth C18

……………………………………………………………………………………………………………………………………………

EROCARB SA: Extrusion equipment and crossheads & tooling

EROCARB SA: Extrusion equipment and crossheads & tooling

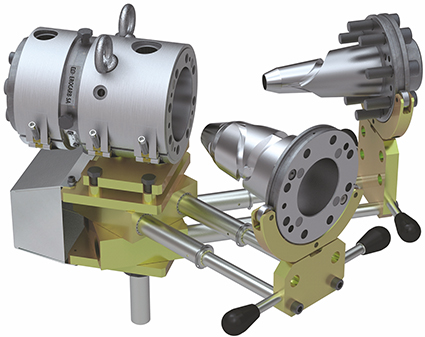

EROCARB SA is a manufacturer of extrusion crossheads and tooling for wire & cable and pipe & tube industries for more than 30 years.

The EROCARB extrusion equipment displayed at the Wire 2014 is dedicated to products from 2 to 200mm and various applications: insulation, sheathing/jacketing, filling-sheathing, triple layer CV line, flat ribbon insulation, medical and irrigation tube.

These crossheads are equipped with centring devices suited for the specific production line. Customers may choose the option: Fix or “Fine-tuning” centring, Manual or Fix-Manual centring at the front or rear of the crosshead.

Associated to the crosshead series, the maintenance modules ETEL save time and reduce risks and wear: Cleaning process and exchange of tooling will be done easy and safe.

Visit EROCARB SA at

Hall 10 / Booth D61

……………………………………………………………………………………………………………………………………………

ESTEVES GROUP: the global wire die company

Esteves Group is the world’s leading manufacturer of high precision wire drawing and cabling dies and extrusion tooling for wire and cable industry.

Its customers count on its customised tooling to manufacture high-quality cables and wire. Its main vision is to understand customer goals and expectations in order to provide products and services that completely meet customer requirements. The Esteves Group has six manufacturing plants in Asia, Europe and North and South America.

It will showcase products such as:

• Natural diamond wire drawing dies

• Polycrystalline diamond wire drawing dies

• Synthetic single crystal wire drawing dies

• Tungsten carbide drawing die

• Recut dies

• Shaped profile wire drawing dies

• Shaving dies

• Bunching, stranding and compacting dies

• Extrusion tips and dies

• Enameling dies

• Ultrasonic polishing machinery

• Wire polishing machinery

• Microscopes

Visit Esteeves Group at

Hall 10 / Booth C72

……………………………………………………………………………………………………………………………………………

FAINPLAST SRL: Innovative solutions for special products

FAINPLAST SRL: Innovative solutions for special products

Fainplast is a manufacturer of special compounds based on PVC, EVA, PE, PP and other polymers. With its 16 compounding lines, Fainplast has a compounding capacity of over 75,000 MT/year.

In its laboratories, new solutions are studied every day in collaboration with customers to meet the demanding markets.

Products such as LSZH compounds, PVC special compounds and cross-linkable compounds will be showcased at the exhibition.

Fainplast will launch some new cross-linkable HFFR compounds with improved properties and higher extrusion speeds at WIRE 2014.

Visit Fainplast at

HALL 12 / Booth B52

……………………………………………………………………………………………………………………………………………

FSP-one: high technology solid wire and stranded wire

FSP-one: high technology solid wire and stranded wire

FSP-one’s conductors, including SPC and NPC, are used in many fields with very high-quality requirements – from F1 to Airbus. The company is now a world leader in its business, after expanding internationally from its head office and main plant in France. With its technical skills, flexibility and efficient team, FSP-one can provide its customers with conductors according to their requirements.

Visit FSP-one at

Hall 12 / Booth A12

……………………………………………………………………………………………………………………………………………

GCR Eurodraw SpA: The leader in wire equipment

GCR Eurodraw SpA: The leader in wire equipment

GCR Eurodraw is a world leader in the design and construction of plant and machinery for production of bare and plated steel wire, cord and rope for every application.

Its product portfolio includes dry and wet drawing machines, cold rolling lines, cleaning, surface-treatment and plating lines, static and rotating coilers with or without drawing die, vertical and horizontal axis spoolers, multiple spool and coil pay-offs and take-ups, double twist stranders and bunchers, skip stranders, tubular stranders, complete plants for PC wire and strand, saw wire, steel tire cord, hose wire, bead wire, wire ropes, welding wire, staple wire, stainless steel wire and other wire products.

GCR Eurodraw SpA will be displaying a full range of equipment designed for wire industry. This year the company will focus on fine wire equipment and will showcase the following equipment:

• A newly developed TCOW 6 cones wet wire drawing machine for very thin wire (SAW wire), fully functional

• A new MTSR 400 dry drawing line equipped with micro rolling cassettes for the production of flux cored welding wires (low carbon steel and stainless steel)

• A new and very interesting DT 6+1/250 double twist buncher for the production of elementary strands with 7 wires

• High-speed rewinding line for welding wire (K300, D300 and D200)

Some of the above equipment will be operated during the exhibition so that visitors can have a clear understanding of it.

Visit GCR at

Hall 11 / Booth A66

……………………………………………………………………………………………………………………………………………

When it comes to protecting cabling infrastructure, the H&R Group is acknowledged as being the only manufacturer in the industry offering both water blocking technology and dielectric compounds for the telecommunication, fibre optic and medium to high voltage power sectors.

H&R offers its customers a robust and flexible supply, having manufacturing sites in Europe, Asia and South Africa. These are supported by international technical and sales teams.

Within the telecoms, fibre optic and power sectors, both utilities and cable manufacturers rely on H&R products to protect their cables. These products include:

• Insojell, Dijell and Naptel petroleum jellies.

• Optifill and Rheogel thixotropic gels for cable filling and flooding

• T Series of dielectric fluids for high voltage AC paper insulated cables.

• Napelec and ND impregnating compounds for MV AC cables.

The group has introduced a number of innovative products, including the H2000 range of hydrogen-absorbing gels for OPGW, OPPC and submarine fibre optic cables.

Additionally, in house innovation has allowed the development of Aquaswell liquid SAP, which has given designers and manufacturers particulate-free water-swelling coating technology, resulting in new cable water blocking opportunities.

Visit H&R at

Hall 12 / Booth C66

……………………………………………………………………………………………………………………………………………

M+E: Specialist in pay-offs, take-ups and wet drawing machines

M+E specialises in the design and manufacturing of pay-offs-take-ups for steel and stainless steel wires in coils-spools for annealing, patenting, galvanizing, brass and bronze plating, oil tempering processes and wet drawing machines, covering a wire range from 0,010 to 25 mm.

M+E’s manufacturing programme includes:

• Pay-offs from coils and spools

• Rotating capstan take-up frames (with flat-grooved or V-grooved capstans)

• Stationary capstan take-up frames with pattern laying (with flat-grooved or V-grooved capstans)

• Spool take-up frames (with or without accumulation capstans for continuous operation)

• Wet drawing machines with standard or automatic spoolers

Visit M+E at

Hall 10 / Booth H43

……………………………………………………………………………………………………………………………………………

InnoVites: Driving the dimensions of your business

InnoVites: Driving the dimensions of your business

InnoVites B.V. will showcase its Cable ERP software at the WIRE 2014 show. InnoVites offers wire and cable industry a complete business solution based on the powerful and popular Microsoft Dynamics AX software. The InnoVites Cable ERP software is fully integrated with CableBuilder, the popular cable design software of our partner Cimteq.

At the Wire 2014 InnoVites and Cimteq will also launch CableMES, which is based on the Wonderware MES platform. CableMES further complements the best-of-breed solution suite that the companies offer to wire and cable industry.

InnoVites will be presenting its IT solutions for wire and cable industry at the show.

Visit InnoVites at

Hall 11 / Booth C22

……………………………………………………………………………………………………………………………………………

Joachim Uhing GmbH & Co. KG comes with new product models and fascinating studies in the luggage to this year’s Wire fair.

A model that Uhing will showcase is a simple winding assembly. It lets you very easily synchronise the winding speed of the spool and the traversing speed without requiring electronic components.

The next assembly is an exciting rolling ring study demonstrating how the linear running direction of the gear can be changed individually and without mechanical intervention while the shaft continues rotating in the same direction. A wide range of stroke speeds can be set almost continuously with the shaft rotating at a constant speed. The pitch can be changed with a stepping motor controlled by data from connected sensors or by direct user input.

Another rolling ring gear attraction is a solution for travelling winders. This offer specifically addresses manufacturers of winding material that must not be deformed during traversing.

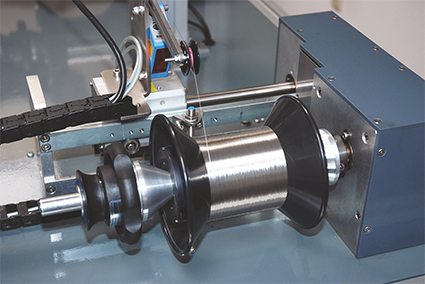

The non-contact flange detecting system is another outstanding invention of the engineering company headquartered in Schleswig-Holstein renowned for its rolling ring drives. FA II, the second generation of this system, will be rolled out in Düsseldorf. A new feature is the ability of automatically detecting the width of spools and the flange type – straight or other than 90 degrees. FA II automatically adapts to the new position and width when a spool of different width has been inserted.

The system is designed to handle round material with diameters from 0.1 to 2.0 mm to be wound on cylindrical spools. It can be used for rectangular or conical flanges up to an angle of 40°. As bent flanges are compensated for, the spools can be filled entirely.

The “RS Sand” study involving a linear drive nut will certainly find its admirers. It proves: The linear drive nut operates smoothly and without being damaged even if it is permanently surrounded by dirt such as very fine sand.

Visit Joachim at

Hall 11 / Booth B40

……………………………………………………………………………………………………………………………………………

Maillefer: Providing superior technology, know-how and service

Maillefer: Providing superior technology, know-how and service

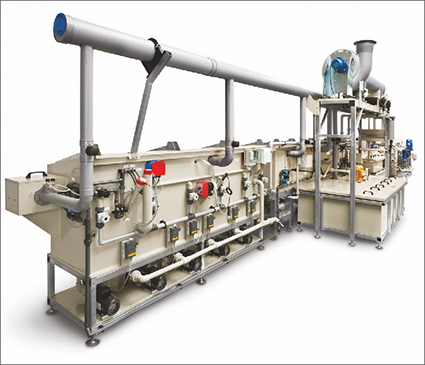

Maillefer is a global leader in providing complete extrusion solutions serving both wire & cable and pipe & tube manufacturers worldwide. The progress achieved together with customers comes not only from our supply of technology know-how and equipment solutions, but also from products with high-added value. Maillefer offers a wide range of services and maintenance packages, product cost and materials saving solutions, as well as insulation cleanliness and quality improvement solutions.

With customer value targets in mind, Maillefer is expanding the wire & cable product portfolio beyond the high performance range. New products are being launched in order to fulfil the more diverse needs coming from customers who are less concerned with possessing the highest production performance available. The different requirements and customer value demands are coming, for example, from the world’s developing markets. In response, a medium voltage and a building wire insulation line have been developed. Both newcomers use the Maillefer extrusion standard, tested in more than 4,000 installations. And more new solutions are on their way.

The current product families available from Maillefer are energy cables including manufacturing solutions for producing automotive, building, LV, MV, HV and EHV cables; fiber optic cable manufacturing solutions for buffering and jacketing fiber optic cables; plastic pipe manufacturing technology; solutions for producing heating and plumbing, medical, automotive, irrigation, water and gas pipes; and telecom cable making including solutions for producing telecom, LAN, coax and specialty signal cables.

Maillefer has sales and service support, production facilities, development and testing capabilities in Finland and Switzerland. Its regional sales and service offices are established in China, Egypt, India, Russia and the USA.

Visit Maillefer at

Hall 10 / Booth D21

……………………………………………………………………………………………………………………………………………

Mathiasen Machinery: Used equipment specialist

Mathiasen Machinery buys and sells used wire and cable machinery internationally. Machinery is purchased for inventory or it can be sold on an exclusive basis. MMI has interest in locating individual machines, complete lines or entire plants. Consignments, warehousing, appraisals and liquidation services are also offered. MMI has buyers seeking all types of good quality used wire and cable machinery. It serves the domestic and international ferrous and non-ferrous wire machinery markets.

Visit Mathiasen Machinery at

Hall 12 / Booth 52

……………………………………………………………………………………………………………………………………………

Medek & Schörner: Cable marking systems

Medek & Schörner: Cable marking systems

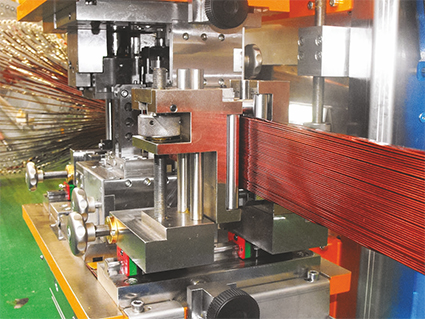

Medek & Schörner will be presenting and demonstrating the following high-performance cable marking machines at the WIRE 2014 Düsseldorf fair:

Cable Marking Machines

• High quality gravure printers (LAN cables, control cables, etc.) for speeds up to 1200 m/min,

• Water Misting unit for the application of fine water dust for pre-cooling of the hot wire immediately after the extruder.

• Embossing meter markers / hot foil sequential meter markers for highest accuracy of length measurement (power cables, telecommunication cables, optical fibre cables, etc.)

• High performance ring markers for marking telephone wires, switchboard wires, automotive cables, LAN cables.

• Video system for monitoring the print quality of fast-running cable printing machines, e.g. allowing real-time inspection for bad quality and/or missing prints

• Laser Marking System for Cables

Optical Fibre Coating Systems

Top speed optical fibre processing systems:

• Optical fibre colour coding up to 3000 m/min;

• Ring marking of optical fibres;

• Tight buffering up to 1300 m/min;

• Fibre ribbon production with excellent ribbon planarity and for speeds up to 1000 m/min.

• CFU Production of compact fibre units

Thanks to the modularity and flexibility of its systems, Medek & Schoerner as one market leader in coating machines for optical fibres was able to implement other applications, including some outside the field of optical fibres:

• Copper wire insulation with UV varnishes (enamelled wire)

• Manufacture of dimension-sensitive precision micro flexible flat cables (FFC) using UV resins

For decades now, Medek & Schörner has been a world market leader in cable marking machines and optical fibre processing lines.

Visit Medek & Schörner at

Hall 10 / Booth A56-01

……………………………………………………………………………………………………………………………………………

METALUBE Ltd: Global specialists in high-performance lubricants

METALUBE Ltd: Global specialists in high-performance lubricants

METALUBE® is launching its all new Lubricool 260 superfine copper wire drawing lubricant. This welcome addition to the Lubricool range uses innovative chemistry that provides significantly improved lubricity. This gives a much cleaner wire that, in turn, reduces wire breaks.

METALUBE® is a UK-based manufacturer of specialist industrial lubricants, exporting to over 80 countries worldwide. Research and development is key to its business and the company constantly invests in the METALUBE Technology Centre based at its Manchester factory, ensuring technical excellence and innovation across its entire range of products and services.

Visit METALUBE at

Hall 11 / Booth G25

……………………………………………………………………………………………………………………………………………

Microdia S.A. : Your expert in extrusion

Microdia S.A. : Your expert in extrusion

As the show, visitors must take a look particularly at the following:

• Ecomex 20 SLS THRG, thermostatic fixed centre single layer + stripe or skin with quick stripe or skin colour change specially designed to extrude cross linkable copolymers on CV lines. This crosshead has gum space adjustment from the rear.

• Avantis 10 DLS, fixed centre cross head two layers + engineered to extrude XLPE or XLPE+LSZH photo-voltaic cable insulation.

• MFLEX 9000-10 SFS skin-foam-skin + stripe fixed center with fine micro tuning developed to run cat 7 & 8 LAN wires.

• MF 9000-20 SLS H, fluoropolymers single layer fixed centre cross head, single layer + skin/stripe.

Visit Microdia at

Hall 11 / Booth D27

……………………………………………………………………………………………………………………………………………

Otomec: Cleaning & plating plants

Otomec: Cleaning & plating plants

Otomec is a leading company that designs, produces and sets up cleaning and plating plant for different products: wire, metal strips and sheets, bars, tubes, chains, etc., of steel and for non-ferrous metals such as copper, brass, aluminum, plated by zinc, tin, copper, nickel, silver and other special alloys like the very new Zinc Nickel Alloy on steel wires or strip that is performing high protection to corrosion.

The “Off’ Line“ process is continuous , reel to reel , coil to coil , bar to bar and completely controlled by electronic devices in regards of speed , tension , thickness of deposition. The “In-Line“machines can work with existing the wire drawing machines.

The process speeds can vary from 10 to 1,000 meters per minute, according to the size of product to be plated and the thickness of deposition.

Special cable manufacturers are using Otomec plants for aerospace, aircraft, high frequency and high tech application such as silver or nickel on aluminum and silver, gold, tin, nickel on copper.

Steel wire manufacturers are using Otomec plants for rust protection and cosmetic properties such as bright zinc, nickel, copper and the very new zinc nickel alloy.

The company’s Oto’ff Line Model MICROPLATER for copper and aluminum wires plating will be showcased at the show.

Visit Otomec at

Hall 11 / Booth B28

……………………………………………………………………………………………………………………………………………

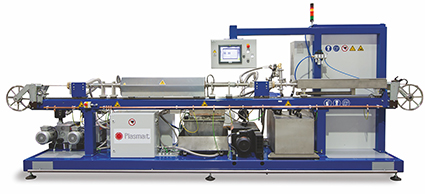

Plasmait: Supplier of plasma based heat and surface treatment solutions

Plasmait: Supplier of plasma based heat and surface treatment solutions

Plasmait is a supplier of heat and surface treatment solutions based on plasma technology for continuous and batch applications in the ferrous and non-ferrous metals industry. Plasmait will present a range of machines including:

• PlasmaANNEALER, which is a heat-treatment machine for stainless steel, nickel and copper alloys. The machine can be used for various sizes and forms of wire, tube ad strand. PlasmaANNEALER is most effective for high-speed annealing of fine stainless steel, nickel alloy wire in-line with rolling or drawing.

• PV Ribbon Line for rolling, annealing, tinning of super-soft PV ribbon.

• PlasmaPREPLATE, which is heat and surface treatment machine for heating, cleaning, deoxidation and surface activation for coating, hot dip and electroplating applications. Plasma PREPLATE is used also for electroplating or hot dip tinning of aluminium wire.

• PlasmaCLEANER, which is a plasma surface treatment machine designed for pre-heating, surface cleaning, degreasing or deoxidation on ferrous and non-ferrous wires, tubes or strip.

• PlasmaGRAPH, which is graphite degreasing for tantalum, tungsten, molybdenum, high speed steel.

Plasmait’s solutions are supplied to wire, cable, tube and strip manufacturers and are most beneficial in the applications with demanding surface and material requirements.

Applications/Materials

• Stainless steel nickel alloys

• Resistance/heating alloys

• Medical wires, tubes, strips

• Fine wire for filters, mesh, knitting

• Aerospace, electronics, oil and gas applications

• Copper and copper alloys, superconductor

• Plating, coating, enamelling and taping

• Precious metals and jewellery and decorative

• Titanium, tungsten, tantalum, molybdenum

• Welding wires

Visit Plasmait at

Hall 10 / Booth A56-8

……………………………………………………………………………………………………………………………………………

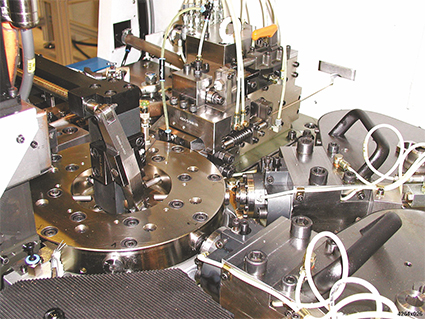

Proteco is specialised in research, development and construction of machines and complete lines for the production of Continuously Transposed Cables. In the field of such sophisticated products, Proteco has introduced highly innovative technologies.

More than 30 installations have been realised so far, and the list of references includes numerous clients all over the world.

Proteco designs its machines with the most modern computerised instruments, manufactures them in its workshop with materials and components of European or American origin and tests them thoroughly in every detail.

Visit Proteco at

Hall 9 / Booth F74

……………………………………………………………………………………………………………………………………………

PS Costruzioni Srl: Citizens of the world

PS Costruzioni Srl: Citizens of the world

Italy’s PS Costruzioni’s technology is used around the world, depended on by leaders in electrical cable because of its reliability. A family business with a heritage of know-how and a willingness to experiment, it offers a wide range of packaging equipment that includes automatic coil winding lines, automatic spool winding lines, automatic coil and spooling lines as well as semi-automatic lines, all of which are designed to provide high-speed processing technology that ensures a final product that is ready to ship to customers.

The company has also developed designing and manufacturing of Rewinding lines and recently designed and manufactured a new Motorised Double Spooler.

This machine can wind up several cable lengths, according to the cable diameter as well as the spool dimensions (for a length up to 500 meters or more).

Visit PS Costruzioni at

Hall 10 / Booth B21

……………………………………………………………………………………………………………………………………………

ROSENDAHL Maschinen GmbH: Cable & Wire Manufacturing Solutions

ROSENDAHL Maschinen GmbH: Cable & Wire Manufacturing Solutions

Made in Austria: European quality is a synonym for a high standard. And this is what ROSENDAHL is known for in wire and cable industry. Its quality makes it a leading global supplier of high-tech cable manufacturing solutions. It offers first-class products and turnkey solutions in the fields of Extrusion, SZ Stranding, Fiber Optic Cable as well as Forming, Welding and Corrugation.

Made in Finland: NEXTROM is its sister company in Finland – a premium supplier of Optical Fibre Glass Preform manufacturing equipment. Here is being developed what today’s technology requires – Fiber Draw Towers and associated machinery for the global fibre market using MCVD, OVD and VAD technologies. Besides providing optical fibre equipment, Nextrom is the world leading supplier of Fiber Optic Cable production lines.

Together ROSENDAHL & NEXTROM offer first class products and turnkey solutions combining leading edge know-how and state of the art technology in close cooperation with its customers and product suppliers.

ROSENDAHL & NEXTROM will present latest advancements and technology highlights, including the latest developments for the production of energy, automotive, communication, optical fibre and fibre optic cables. A special highlight will be its technology for continuous welding.

Visit ROSENDAHL at

Hall 9 / Booth A60

……………………………………………………………………………………………………………………………………………

RSD Group: Printing on wires, cables, hoses & tubes

The Group can meet all the requirements of industrial contact printing in the cable, hose and profile industries. The German headquarters, RSD Technik GmbH, is an ISO 9001:2008 certified company. With RSD Hi-Tech Industrial (Shenzhen) Co. Ltd. and RSD Hi-Tech Industrial (Shanghai) Co., Ltd. as well as various sales and production sites in America and Europe, the RSD Group is a synonym for high-quality and speedy delivery worldwide.

At the show, it will showcase high-speed printing machines for wire and cable industry.

Visit RSD Group at

Hall 10 / Booth H72

……………………………………………………………………………………………………………………………………………

SIKORA: Technology to perfection

SIKORA: Technology to perfection

At the world’s leading fair for the wire and cable industry, the WIRE 2014, SIKORA will be presenting a broad product range of innovations as well as proven technology for quality control and cost saving at the wire and cable production.

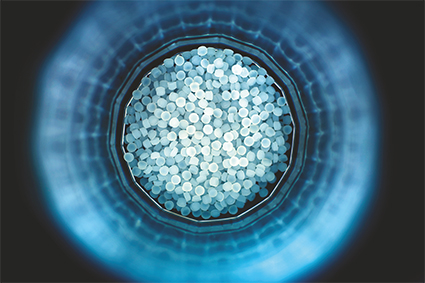

The highlight at SIKORA’s booth is the newly developed PURITY SCANNER. The PURITY SCANNER is a system for the online inspection and sorting of plastic pellets used for the insulation of medium-, high- and extra-high voltage cables, but as well for other applications such as the medical industry. Contaminated pellets are separated and blown out, assuring that only pure pellets get into the extrusion process. The pellet inspection allows the detection of organic and metallic contaminations inside the pellet as well as on the pellet surface, using a special combination of X-ray technology and an optical system. The smallest detectable particle size is 50 µm at a flow rate of up to 2,000 kg/h.

In addition to SIKORA’s successful diameter gauges of the classic-line LASER Series 2000, SIKORA offers the top-line LASER Series 6000. These diameter-measuring devices are specifically designed for sophisticated customer requirements that exceed the classic demands in the wire and cable industry. The gauges fulfill all needs regarding high accuracy, a variety of interface connection options and utmost reliability for a quality control at its best during wire and cable production. The high accuracy allows in addition the detection of lumps and neckdowns. Three gauges are available for different product diameters from 0.2 to 78 mm.

Another attraction at the SIKORA booth is the PREHEATER 6000 TC (Temperature Controlled), which represents the optimum solution for the controlled preheating of conductors and sets the basis for the production of a broad cable type array at highest quality.

SIKORA also showcases the new WIRE-TEMP 6000, a system for continuous online temperature measurement of metallic and insulated conductors on a non-contact basis.

In addition to the latest technological highlights, SIKORA shows among others the TIGER LASER 6010 XY for diameter measurement and simultaneous lump detection, as well as the 2- or 3-axis lump detectors LUMP 2000 XY/T.

SIKORA also exhibits the X-RAY 8000 NXT for quality control during the production of MV, HV and EHV cables in CCV-, VCV- and MDCV-lines.

Visit Sikora at

Hall 09 / Booth A41

……………………………………………………………………………………………………………………………………………

Star Material

Star Material is a joint venture company by “Suzhou Zhihong Cable Materials”, a professional wire & cable material manufacturer in China since 1998, and two professionals from Europe with almost 30 years of experience and background in wire & cable industry.

During the show the company will showcase AL/PET tape, PET tape, CU/PET tape, mica tape, non conductive and semi-conductive water blocking tape and binder tape, fibreglass tape, PP yarn, water blocking yarn, polyester yarn and ripcord.

Visit Star Material at

Hall 16 / Booth G38

……………………………………………………………………………………………………………………………………………

TROESTER: Tradition for innovation

TROESTER: Tradition for innovation

The TROESTER Group is a worldwide leading manufacturer of complete extrusion systems for the cable industry. The excellent results produced by its extrusion technology makes TROESTER a competent and reliable partner in the cable industry.

This year TROESTER will present its state-of-the-art extrusion equipment for the production of LV, MV, HV and EHV cables. This comprises CCV and VCV Lines, Insulation and Sheathing Lines as well as ingle machines and components for efficient cable production.

X-Compound, the new company of the TROESTER Group will join the booth and present their kneader technology for the continuous compounding of HFFR (LSOH), PVC, XLPE, Semi-conductive Materials and EPR/EPDM. X-Compound is specialized in the planning and construction of complete systems for the compounding of plastics with the process steps conveying, melting, dispersing, mixing and degassing.

Visit TROESTER at

Hall 10 / F62

……………………………………………………………………………………………………………………………………………

WAFIOS Umformtechnik is among the leading manufacturers of innovative machine technology and tools for cold, warm and hot forming. The main points of our portfolio are cold formers for the production of high quality fasteners made of steel wire, stainless steel, high alloy and exotic materials.

Furthermore, our integrated solutions are completed with secondary operation machines, long-life quality tools and our comprehensive service.

WAFIOS Umformtechnik invites to come to Booth Hall 10F40 on the WIRE SHOW Düsseldorf to have a presentation of the machines:

The 2-die-3-blow former HC5FT and the forming centre SMR will be showcased at the event.

The HC5FT is prepared for induction heating. Customers can form wire made of stainless steel and therefore optimise the cold forming process with induction heating, which is considerably more efficient and productive for these materials.

With its forming centre SMR, the company integrated an automatic solution for the production of screws and small parts. This type combines all individual processes in one machine, runs up to 8 stations fully automatic with high productivity.

Visit WAFIOS at

Hall/Booth 10F40.

……………………………………………………………………………………………………………………………………………

Micro Products Company: Offering the world a better weld

U.S. based Micro Products Company is a leading manufacturer of high-performance Micro-Weld electric resistance butt welders since 1928. It offers over 50 models for continuous processing of steel, copper and aluminum wire, rod or cable, solid or stranded, used in over 30 countries by leading national and international companies.

Visit Micro Products at

Hall 09 / Booth D06-02