October 22, 2014

SIKORA comes up with quite an exhaustive list of products for inspection and sorting as well as measuring and control technology for online quality assurance of energy cables. The product portfolio includes PURITY SCANNER ensuring cleanliness of XPLE pellets, CSS 2 for the cleanliness of the melt, ULTRATEMP 6000 to measure the temperature of the PE melt, X-RAY 8000 NXT for accurate hot measuring values of the cable parameters, and X-RAY 8700 NXT to provide precise cold values.

PURITY SCANNER

PURITY SCANNER assures cleanliness of XLPE pellets. It assures a 100 percent online inspection and automatic sorting of PE pellets. The PURITY SCANNER intelligently combines X-ray technology with an optical system. This allows the detection of metallic and organic impurities of 2 mil (50 μm) in the pellet itself and on its surface to 100%. Contaminated pellets are detected and sorted out in order to ensure that they do not get into the extrusion process.

The purity of XLPE pellets as they are used for the insulation of medium, high, and extra-high voltages cables as well as for on- and offshore cables is a decisive characteristic for the quality of the end product.

CSS 2

CSS 2 assures the cleanliness of the melt. In a CV-line, for example, a CSS 2 (Cleanliness Scanning System) is installed for real time monitoring and detection of impurities of the polymer melt. The flow channel between main extruder and the cross head is equipped with sight glasses and an optical CCD color camera system, which inspects the insulation material. The CSS 2 detects contaminants down to a size of 20 μm and distinguishes between metallic contaminants, scorches and ambers of selected sizes.

ULTRATEMP 6000

ULTRATEMP 6000 assures an optimum melt temperature. It measures the temperature of the PE melt during extrusion on a non-contact basis between the extruder screw and the cross head. Besides temperature determination, it detects inhomogeneities in the melt. Early cross linking after screens which may lead to ambers or scorches in the material can be avoided by this reliable ultrasonic temperature measurement. The device optimizes the output of a planned production time.

X-RAY 8000 NXT

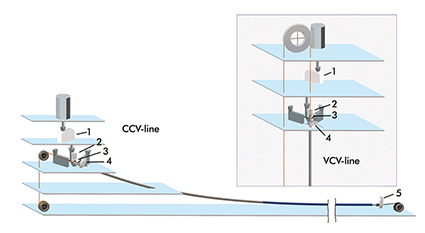

X-RAY 8000 NXT assures accurate hot measuring values of the cable parameters. This X-ray measuring system is installed in the moving part of the telescopic tube directly after the crosshead for precise measurement of the wall thickness of all 3 layers (concentricity, diameter and ovality) directly after the triple crosshead. Measuring values for centering and control are therefore available immediately after starting up the line. The system is used in catenary and vertical lines.

X-RAY 8700 NXT

It assures precise cold values. While the X-RAY 8000 NXT provides information for a fast centering and direct control, the X-RAY 8700 NXT supplies precise quality data of the final product. The X-RAY 8700 NXT measures the diameter, wall thickness and eccentricity and is suitable for all cable types with solid, stranded or Milliken conductor and with single, double or triple layer insulation. With the use of the X-RAY 8000 NXT at the beginning of the line for collection of the hot measuring values and the X-RAY 8700 NXT at the end of the line for measuring the cold values, 3 shrinking values are analyzed for every insulation layer of the cable. Consequently, an optimum process is assured.