European Constructions Products Regulation (CPR) considers the ‘cables’ now under the classification system of products because of concluded CEMAC and following the proposition by SP Fire Research to European Commission.

The fire properties of cables are of great importance from a fire safety perspective. As a result, cables have been included in the classification system under the European Construction Products Regulation (CPR), following SP’s proposing of the classification system to the European Commission. The European CEMAC project (CE-Marking of Cables), for which SP Fire Research has provided technical management, has recently been concluded. The results of the work will significantly reduce the volume of testing required for CE-marking of cables in Europe according to the CLC/TS 50576 standard for extended field of application (EXAP).

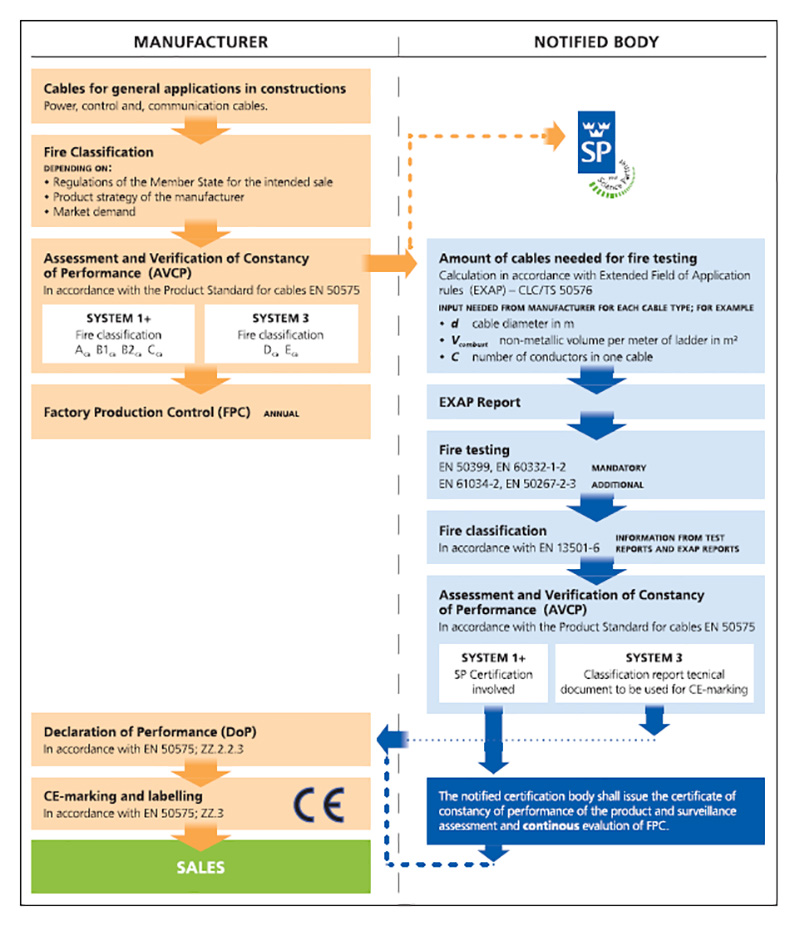

The Road to CE-Marking

The objective of the CPR, which regulates building products on the European market, is to ensure the free movement of all construction products within the European Union with respect to the essential health and safety requirements. When it comes to cables, safety in the case of fire is the only requirement. An additional objective of the regulation is to standardize the manufacturing of construction products and guarantee their unlimited use within the EU.

The CPR consists of four main elements:

• A system of harmonized technical specifications

• An agreed upon system of attestation of conformity for each product family

• A framework of notified bodies

• The CE-marking of products

The Regulation is not intended to harmonize regulations/building codes, as EU Member States are free to set their own requirements regarding the performance of works and, therefore, products. Instead, its objective is to harmonize the methods of testing, declaration of product performance values, and conformity assessment. The choice of value for intended use (fire technical classifications) is left to the regulators of each Member State.

When a construction product is covered by a harmonized standard, the manufacturer is required to draw up a declaration of performance (DoP) when it is placed on the market. This means that the manufacturer is responsible for the conformity of the construction product to the DoP.

For any construction product to which a harmonized standard applies, the CE-marking should be the only sign or symbol visible on the product. This marking visually signifies that the pro-duct conforms to the specifications of the harmonized standard it is covered by.

In order to obtain a CE-marking for cables, there are certain steps and procedures that the manufacturers must go through and comply with. These are described below.

The Product Standard EN 50575 Will Make CE-Marking Possible

In September 2014, the CENELEC TC 20 (European Committee for Electro-technical Standardization, Technical Committee 20) published a product standard for cables; EN 50575 (Power, control and communication cables. Cables for general applications in construction works subject to reaction to fire requirements). EN 50575 is expected to be published in The Official Journal of the European Union (OJ) in mid-2015. The OJ is the official compendium of EU legislation (L series) and other official documents of the EU institutions, bodies, and agencies (C series and its supplements).

This means that all cable manufacturers who intend to sell cables for use in permanent installations in buildings in Europe must obtain CE-marking for their products. Once the standard is published in the OJ there will be a transitional period, which has not yet been defined.

Extended Field of Application Rules (EXAP)

The EXAP standard CLC/TS 50576 allows a limited number of cables belonging to a larger group (‘family’) of cables to be fire-tested. The results of these tests are interpolated for the classification of part of, or the entire, cable family. This eliminates the need for the extensive testing of the individual cables of a cable family that can be expected to have the same fire behavior. In most cases, EXAP is a prerequisite for CE-marking.

In SP’s process, cables are reviewed and grouped by product families. Based on the EXAP rules and whether a “Specific” or “General” EXAP rule is being worked with, two or three cables from each family are chosen for type testing and specified in an EXAP report.

Compulsory Fire Test Standards

Manufacturers must test the cables specified in their EXAP report in accordance with two compulsory standards:

• EN 50399 (Common test methods for cables under fire conditions – Heat release and smoke production measurement on cables during flame spread test). This is the most commonly used fire test for cables. Measured quantities are Flame Spread (FS), Heat Release Rate (HRR), Total Heat Release (THR), Fire Index Growth Rate (FIGRA), Smoke Production Rate (SPR), and Total Smoke Production (TSP). Toxic gas species can also be measured using Fourier Transform Infrared Spectroscopy (FTIR).

• EN 60332-1-2 (Tests on electric and optical fibre cables under fire conditions – Test for vertical flame propagation for a single insulated wire or cable). In this test, a flame with 1 kW of heat output is applied to a single cable. The measured quantity, H, is the length of the com-busted or charred section of the cable.

Fire Classification

There are seven fire classes specified in EN 50575: Class Aca relates to non-combustible products, e.g. cables with ceramic insulation. Class B1ca refers to products which are combustible, but which contribute least to the spreading of fire, while B2ca and Cca represent products which may spread a fire to some degree. Products in Class Dca have fire characteristics similar to those of ordinary wood, while Eca consists of products that are not easily ignited by a small flame, but for which there are no requirements with regard to heat and smoke release. Fca indicates that no performance class has been determined. Comparing this system with that for surface-covering materials, in which Euroclass A is non-combustible and Euroclass D represents wood, it can be seen that the two run parallel.

The product strategy of the manufacturer, as well as the demand of the market, guides the manufacturer as to what fire technical class to obtain. In addition, and as discussed above, each European country’s building code will specify which fire classifications are required.

Classification Report

The results of the fire tests are presented in reports, which are then used as a basis for a classification report in accordance with EN 13501-6 (Fire classification of construction products and building elements. Classification using data from reaction to fire tests on electric cables).

The classification report provides the manufacturer with the basis for the CE-marking of cables in accordance with EN 50575.

Which AVCP System Will Apply to the Product?

EN 50575 specifies which Assessment and Verification of Constancy of Performance (AVCP) system should be applied to the products from each fire class, along with the responsibilities of the manufacturer and the Notified Body (NB) with regard to the CE-marking process.

For System 1+, the manufacturer shall carry out:

• Factory production control

• Further testing of samples taken at the factory in accordance with the prescribed test plan

For System 1+, the notified product certification body shall issue the certificate of constancy of performance of the product on the basis of:

• Determination of the product-type on the basis of type testing (including sampling), type calculation, tabulated values, or descriptive documentation of the product

• Initial inspection of the manufacturing plant and of factory production control

• Continuous surveillance, assessment, and evaluation of factory production control

• Audit-testing of samples taken before placing the product on the market

For System 3, the manufacturer shall carry out factory production control, and the notified testing laboratory shall carry out determination of the product-type on the basis of type testing (based on sampling carried out by the manufacturer), type calculation, tabulated values, or descriptive documentation of the product.

Fire Resistance

There is also ongoing standardization work within CENELEC with regard to the fire resistance of cables. The main standard being discussed is prEN 50577 (Electric cables – Fire resistance test for unprotected electric cables (P classification)). Its purpose is to evaluate the ability of a cable to maintain electrical circuit integrity throughout a defined time period, during exposure to fire under the conditions of the EN 1363-1 standard time/temperature curve and when installed in standardized, representative conditions. SP currently offers tests according to this preliminary standard.

When prEN 50577 is formally published, fire resistance will also be included in the classification system under the CPR. As a result, it will be a compulsory requirement for cable manufactures to fulfill.

The Future

At first glance, the system’s specifications might appear to be somewhat difficult to fully meet. SP is aware of this, however, and is ready to assist cable manufactures, by grouping cables in product families in accordance with the EXAP standard CLC/TS 50576. This will considerably reduce the number of tests needed. SP can also guide cable manufacturers through the European system, and assist cable manufactures in maximizing product approvals through reducing the number of tests.

Many cable manufactures have started the process of fire testing their products, in order to be prepared for the publishing of EN 50575. Doing so will ensure that CE-marking certificates may be efficiently and swiftly issued.