X-ray technology combined with high resolution optics for the detection of contamination

April 4, 2015

The purity of XLPE pellets, as they are used for the insulation of medium, high, and extra-high voltages cables as well as for on- and offshore cables, is a decisive characteristic for the quality of the end product. Damages caused by breakdowns due to contaminated material can easily run into the millions. Therefore, the production of highly clean material as well as the continuous detection and sorting out of contaminated pellets before they get into the extrusion process is of essential importance.

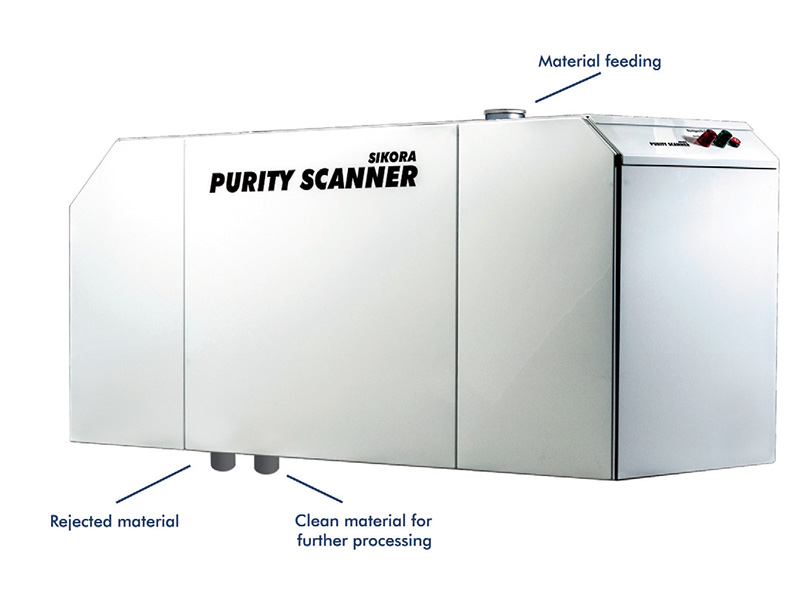

With the PURITY SCANNER, SIKORA provides an unrivaled, user oriented system for a 100% online inspection and automatic sorting of XLPE pellets.

Unique Combination of X-Ray and Optical Technology

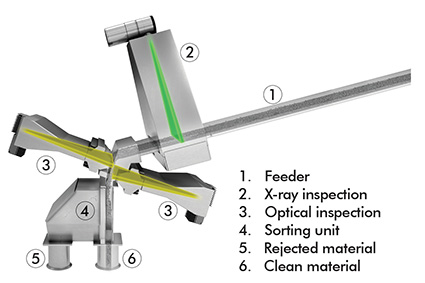

The PURITY SCANNER intelligently combines X-ray technology with a dual-axis optical system. This allows the detection of metallic and organic impurities of 50 µm in the pellet itself and on its surface. Contaminated pellets are separated and sorted out in order to prevent that they get into the cable insulation.

The application of both technologies is unique and exceeds previous solutions on the market. Due to the specially developed X-ray technology, the PURITY SCANNER inspects colored (e.g. black) pellets as well as semi-conductive XLPE material for impurities and sorts them out automatically.

Innovative Feeding System

The progressive PURITY SCANNER does not only feature a unique inspection technology, but also a novel transport system of the pellets. The feeding of the pellets is carried out via a vibrating ramp. The material does not come into contact with the ambient air as the transport system is hermetically sealed. Absolute purity is guaranteed. The system is designed for a throughput of 500, 1,000 or 2,000 kg/h and can easily be integrated into existing feeding systems.

Integration of the System in the Production Line

The system is typically installed between the hopper that is fed from the XLPE supply (octabin, bag or silo) and the hopper of the extruder, whereas the compound is fed by gravity. The transport system of the PURITY SCANNER is hermetically sealed assuring that there is no risk that dust or other contaminants can get into the flow of XLPE pellets. In addition, the transport system can be operated with an overpressure.

With the PURITY SCANNER, the production process in the cable industry is improved significantly and, thus, the safety and life time of the cable is increased.

Cleaning Concept

When designing the PURITY SCANNER, it was the utmost priority to create a system that remains long-time clean. Accordingly, the transport system is integrated into an encapsulated housing with slight overpressure in order to prevent contamination entering the system from the outside. In the event that cleaning of the system is required, the system can be easily and quickly opened and cleaned. Furthermore, the Cleaning Concept was developed for customers who run different materials respectively colors and want to clean the system when changing the material. In addition to cleaning, there is the possibility to exchange the complete transport system with a cleaned, sealed system.