Chetan Makadia, Joe Vontorcik,

Viviana Wilson and Manish Singh

Abstract

The temperature rating of jacketing material is very important for cable applications. Temperature rating helps users determine operating range of cable products. There are several ways one can determine temperature rating of cable products. One of the widely used methods is to assign temperature rating according to UL 1581. Until recently, TPUs can only be rated at a maximum 80 °C via short term aging as per UL 1581. As such, TPUs were not considered for higher temperature applications. Due to Lubrizol’s proposal, the revision of UL 1581 dated January 30, 2013enables TPU materials to be rated for 90 °C and 105 °C via simple 7 days aging test.

In this paper, data are presented for thermal aging of two TPU grades for 90 °C and 105 °C rating as per UL 1581. Effects of processing variables such as RPM and temperature on mechanical properties of two TPU grades arereviewed. Additionally, post extrusion shrinkage data and effect of processing variables on shrinkage of two TPU grades are presented.At the end, new high temperature TPU technology with ability to get 125 °C rating is reviewed. .

Keywords:Estane; TPU; PU; temperature rating; UL 1581;125 °C; shrinkage, hydrolysis

1. Introduction

Every polymer has its own thermal aging characteristic depending upon chemistry of the polymer and additives incorporated into the product. Generally, polymers age by gradual loss of its ultimate elongation. For wire and cable applications, it is commonly considered that a minimum 50 % ultimate elongation of sheathing material is necessary to ensure cable functions without cracking. Many flexible jacketing polymers obtain flexibility by addition of plasticizers and/or oils. Specific examples include flexible PVCs and some TPEs. Upon thermal aging, these compounds gain tensile strength by loss of oil/plasticizer. However, their ultimate elongation reduces because they become brittle by loss of plasticizing additives. TPUs on the other hand behave the opposite way after thermal aging. Wire and cable TPU compounds are flexible by virtue of their inherent chemistry. No oil or plasticizing additives are added to TPUs to obtain lower hardness and flexibility. After thermal aging at temperatures for 90 °C and 105 °C rating, most polyether TPUs’ tensile strength reduces more than 25 %. However, they stillmaintainabsolute tensile strength well above the functional requirements for cable jacketing applications. Because of original tensile strength loss of more than 25 % , most of polyether TPUs can not be rated 90 °C and higher under TPE categories as per short term aging criteria specified in UL 1581.

As a result of Lubrizol’s initiative, the latest revision of UL 1581 dated January 30, 2013 includes two new tables 50.227.1 and 50.227.2 for 90 °C and 105 °C TPUs respectively. For 90 °C, therating table specifies to maintain 65 % of unaged tensile strength and 70 % of unaged ultimate elongation. For 105 °C rating it is required to maintain 35 % of unaged tensile strength and 85 % of unagedultimate elongation. These new requirements reflect aging behavior of polyether TPUs.

2. Experimental

2.1 Materials

TPUs used in the study were RoHS and REACH complying commercial Estane® TPU grades. TPU-A and TPU-B were flame retardant 85A hardness polyether and non-flame retardant 87A hardness polyether respectively. TPU-C was newly developed TPU for high temperature application capable of achieving 125 °C rating.

2.2 Sample Preparation and Test Method

Specimens used for thermal aging were in tubular form unless noted otherwise. Outside diameter of tube was 6 mm with thickness of 0.8 mm approximately. Tubular specimens were extruded on 1.5 inch single screw extruder on cross head die with 20/40/20 screen pack on the breaker plate. Specimens used for processing study were die cut dumbbells. Oven aging was conducted in forced air circulated oven. Tensile testing was conducted as per ASTM D-412 at 500 mm/min cross head speed. Shrinkage was measured on 152 mm tubular specimens.Data reported are average of five specimens.

3. Results and Discussion

3.1 90 °C and 105 °C TPUs

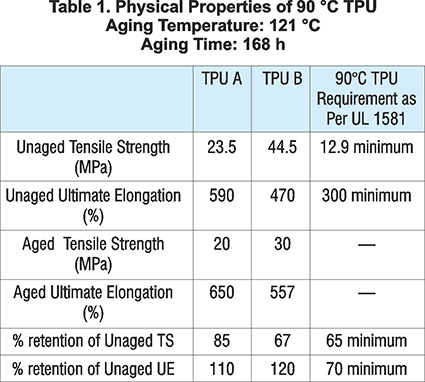

Table 1 shows the unaged and aged tensile properties of TPU-A and TPU-B. For 90 °C rating oven aging was conducted at 121 °C temperature. It can be seen that both TPUs easily passed new requirements of UL1581 for tensile strength. Ultimate elongation values after thermal aging were even higher than their unaged values.

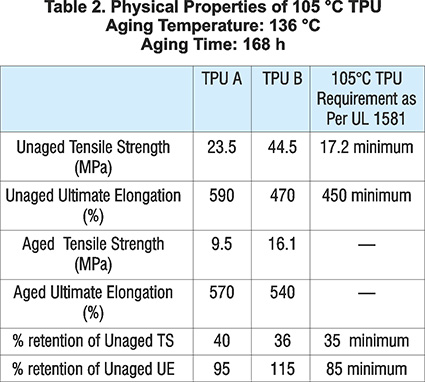

Table 2 shows physical properties of TPU-A and TPU-B for 105 °C rating. UL 1581 only requires maintaining 35 % of original tensile strength after thermal aging for 105 °C TPU. However, original and aged ultimate elongation requirements are very high. Both TPUs tested exhibit typical polyether TPU aging behavior and passes the requirements for 105 °C rating. It can be seen that there was significant reduction in tensile strength after aging at136 °C but ultimate elongation was virtually unaffected.

3.2 Processing Study

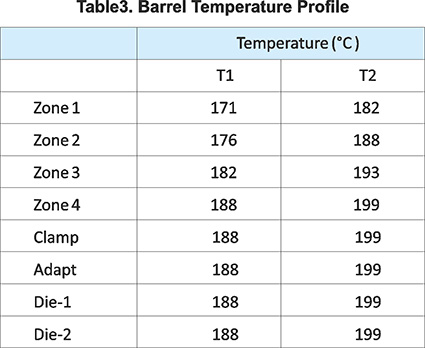

A small processing study was conducted to assess effects of throughput and temperature on tensile properties of TPUs. Processing variables were still within the normal processing window. Table 3 shows the two different barrel temperature profiles T1 and T2 used in this study. Samples were extruded at 10 rpm for both profiles and at 30 rpm for T1 profile.

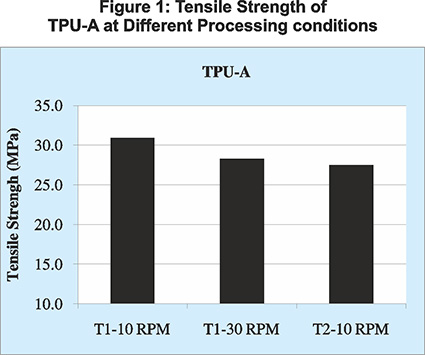

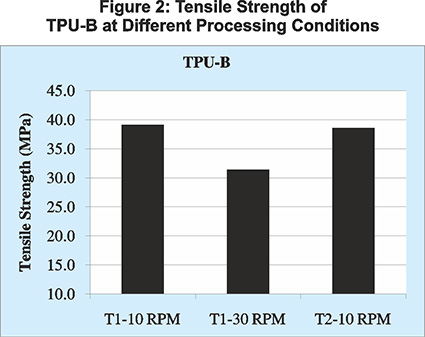

Effect of processing variables on tensile strength is shown in Figure 1 and Figure 2 for TPU-A and TPU-B respectively. As expected for both TPUs best tensile strength was observed at low rpm and low barrel temperatures. At high rpm, tensile strength was reduced marginally but still maintained at high level for both TPUs. High processing temperature only affected tensile strength of the flame retardant TPU. Non-flame retardant TPU-B did not have any significant effect of high temperature on tensile strength.

3.3 Post Extrusion Shrinkage

Post extrusion shrinkage of jacketing material can cause problems with production of optical fiber assembly. Post extrusion shrinkage may impart stresses to optical fibers resulting in less than optimal performance. Unlike other polymers used as sheathing material, TPUs exhibit very little post extrusion shrinkage. Standards for optical cable assemblies usually specify post extrusion shrinkage of 2 % or less.

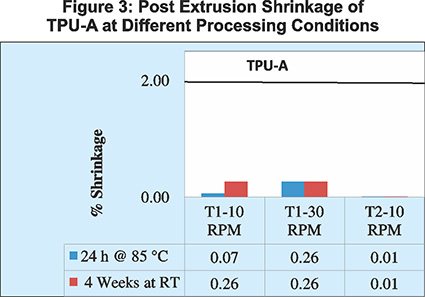

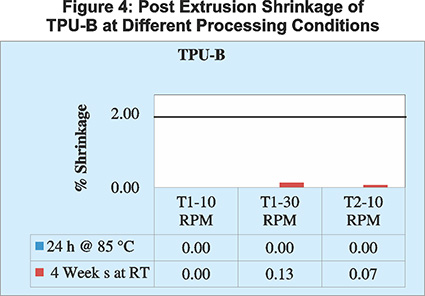

Post extrusion shrinkage at different processing conditions is shown in Figure 3 and Figure 4 for TPU-A and TPU-B respectively. It can be seen that both TPUs show extremely low shrinkage, well below the 2 % requirement after annealing at 24 h at 85 °C and then subsequently conditioning at room temperature forfour weeks. Processing temperature had negligible effect on shrinkage of TPUs studied. Higher rpm resulted in slightly higher shrinkage for flame retardant TPU-A at 24 h but eventual shrinkage at four weeks was similar at both rpms. Non-flame retardant TPU-B had extremely low negligible shrinkage at all conditions.

3.4 New 125 °C High Temperature TPU

Lubrizol has developed new TPU to help cable manufacturer expand their ruggedized cable productsolutions at higher temperatures. New TPU has excellent abrasion and cut through resistance, high flex life, and low temperature flexibility typical of standard TPUs. It improves temperature and chemical resistance performance significantly over conventional TPUs making it highly suitable for demanding applications requiring armor against high temperature, physical abuseand harsh chemical exposures.

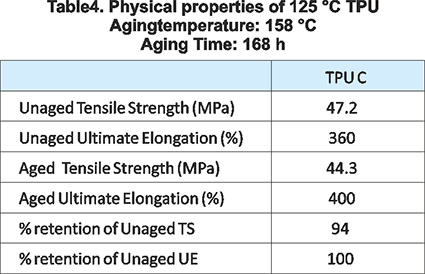

Table 4 shows thermal aging data for TPU-C for 125 °C rating on tubular specimen extruded on crosshead die. It can be seen that tensile strength and ultimate elongation for TPU-C was virtually unaffected after thermal aging. TPU-C maintained more than 90% of original tensile strength at 158 °C for 7 days.

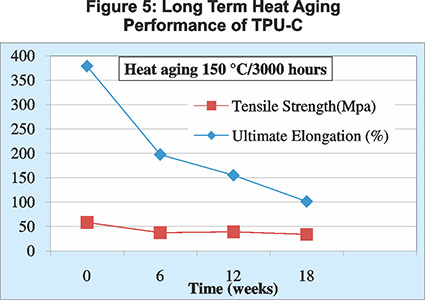

Long term heat aging and hydrolysis performance for TPU-C is shown in Figure 5 and Figure 6 respectively. Tensile properties were measured on die cut specimens from 1mm thick extruded strip. After 3000 h of thermal aging, TPU-C maintained ultimate elongation well above 50 %. For comparison, conventional polyether TPU would lose ultimate elongation completely and become brittle after 6-12 weeks of exposure at 150 °C.

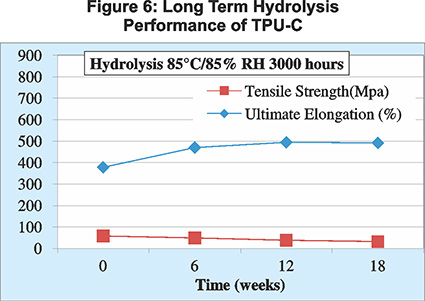

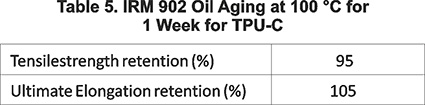

There was no negative effect on ultimate elongation and marginal drop in tensile strength of TPU-C after 3000 h hydrolysis at 85 °C. Table 5 shows excellent oil aging performance of TPU-C.

4. Conclusions

TPU-A and TPU-B are suitable material for 90 °C and 105 °C rated cable applications specifically if applications involves abusive physical or harsh chemical exposures. In processing study, high rpm and high temperatures resulted in slightly reduced tensile strengths of TPUs studied. Both TPU-A and TPU-B showed extremely low post extrusion shrinkage making them suitable for optical cable jacketing applications. New TPU-C expands temperature application to even higher level to 125 °C. New TPU-C demonstrated outstanding oil resistance, long term hydrolysis and long term thermal aging behavior.

5. Acknowledgments

Authors would like to thank Lubrizol Advanced Materials, Inc. for providing the resources to conduct the work. Thanks also to the lab personnel involved in the data collection for the study. Finally, thanks to the IWCS review committee for kindly accepting the paper for presentation.

6. References

[1] UL 1581, Reference standard for electrical wires, cables, and flexible cords.

[2] UL 2556, Wire and Cable test methods.

(Source: Lubrizol Advanced Materials India P. Limited)