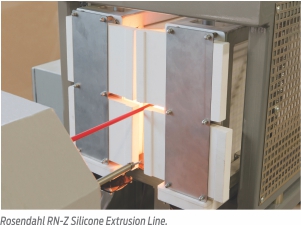

The RN-Z Silicone Extrusion Line performs 24/7 at high speeds and offers utmost productivity. Rosendahl has lines for conductor cross sections from 0.22 to 300 mm².

For all silicone cable manufacturers in search of a supplier who understands their requirements, Rosendahl is the answer who works through the requirements with customers. That way, customers will receive their personal and customized production line that does exactly what is expected.

For all silicone cable manufacturers in search of a supplier who understands their requirements, Rosendahl is the answer who works through the requirements with customers. That way, customers will receive their personal and customized production line that does exactly what is expected.

Then, customers have one big – and mostly essential – benefit. It is a supplier that understands the product, which is very demanding in its material performance, material properties and its application. By knowing the product and its ingredients, and as Rosendahl experts in extrusion technology, it is very familiar with the process. Over the course of its laboratory work, the company has examined possible ways to achieve the best product performance.The company came to the conclusion that the process design demonstrates the best and most optimized results with infrared curing. A perfect crosslinking process is the end-all and be-all in order to keep the material stable and process it into a cable with the required mechanical properties. In so doing, the extruded cable is treated in the shock oven at temperatures of up to 600OC or 800OC.

The RN-Z Silicone Extrusion Line performs 24/7 at high speeds and offers utmost productivity. Rosendahl has lines for conductor cross sections from 0.22 to 300 mm². Its lines guarantee the highest flexibility and the lowest scrap rate during production.