— Marc Jarrault, Managing Director, LAPP India Pvt. Ltd.

Plug-and-play products have risen in popularity due to their ease of use, scalable and reliable operation. The practical extension of this concept, when applied to the whole industrial automation process, has given way to a new term: plug-and-produce. In short, ‘plug and produce’ means flexible manufacturing.

Regardless of the line of business, the pursuit for effective productivity and the desire to produce affordable products that fulfil customer demands are key organisational drivers. To support these objectives and compete in the global marketplace, manufacturing companies in particular are concerned with getting products to market as quickly and inexpensively as possible. Industry 4.0 is the current trend of automation and data exchange in manufacturing technologies. It includes cyber-physical systems, the Internet of things and cloud computing. Industry 4.0 creates what has been called a “smart factory”. The rise and development of the concept of Industry 4.0, as well as the reach of the Industrial Internet of Things (IoT), will make this possible, via the interconnectedness of machines, facilities and systems. This connectivity allows network components and sub-frameworks to self-sufficiently trade data and to control one another. It enables decentralised control of production procedures for smaller batch sizes and makes it possible to have a high number of product variants.

Regardless of the line of business, the pursuit for effective productivity and the desire to produce affordable products that fulfil customer demands are key organisational drivers. To support these objectives and compete in the global marketplace, manufacturing companies in particular are concerned with getting products to market as quickly and inexpensively as possible. Industry 4.0 is the current trend of automation and data exchange in manufacturing technologies. It includes cyber-physical systems, the Internet of things and cloud computing. Industry 4.0 creates what has been called a “smart factory”. The rise and development of the concept of Industry 4.0, as well as the reach of the Industrial Internet of Things (IoT), will make this possible, via the interconnectedness of machines, facilities and systems. This connectivity allows network components and sub-frameworks to self-sufficiently trade data and to control one another. It enables decentralised control of production procedures for smaller batch sizes and makes it possible to have a high number of product variants.

This has given birth to Smart Factories. Smart Factories enables a business to be more plugged into the Industrial Internet of Things. This allows a business to look for ways to identify, isolate and prioritize the predictable and repeatable components of processes. It also helps in minimizing downtime by constantly monitoring the health of the business systems and equipment to identify or even predict problems. As a result, smart factories need to be much more networked than they are today. This has been ascertained in several research projects. This means that even very small components will be able to provide data in the company’s network or even online. Plug-and-produce systems save space on the factory floor and make shorter installation and maintenance times possible. Industry 4.0 is a concept that uses universal networks to link corporate and business processes from the Enterprise Resource Planning (ERP) level right through to the sensor/actuator level. This is the only way to ensure that data from production facilities is supplied directly to the material, planning and production control systems. In addition to standardised communications protocols, standardisation is also required at the physical level. Data cables and connectors play a key role here as manufacturing can only be reliably networked across all levels if a consistent cabling and connection concept is in place.

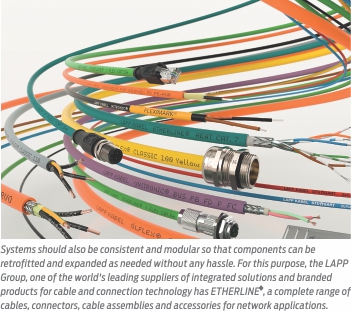

Here comes the need for a backbone, a data cable that enables efficient transferring of data. It needs to guarantee sufficient data rates so that entire machines and components can communicate with each other at the ERP level. Systems should also be consistent and modular so that components can be retrofitted and expanded as needed without any hassle. For this purpose, the LAPP Group, one of the world’s leading suppliers of integrated solutions and branded products for cable and connection technology has ETHERLINE®, a complete range of cables, connectors, cable assemblies and accessories for network applications.

LAPP recommends a Cat.6A Ethernet cable to serve as this backbone. This will future-proof the system, configure it for data rates of up to 10 Gbit/s, offer sufficient reserves and ensure expandability. These “backbone” cables are usually laid securely in cable trays or ducts. However, for larger, moving components the backbone often has to be routed using drag chains. To meet these requirements, Lapp has developed its ETHERLINE® Cat.6A FD cables. They are suitable for drag chain use and guarantee reliable data transmission of up to 10 Gbit/s over several million bending cycles. These ETHERLINE® cables are flexible and improve your total cost of ownership with faster installation and lower downtime. With ETHERLINE® Cat.6A, LAPP recommends the use of M12 connectors where water-tightness and dirt resistance in accordance with IP67 are required.

LAPP recommends a Cat.6A Ethernet cable to serve as this backbone. This will future-proof the system, configure it for data rates of up to 10 Gbit/s, offer sufficient reserves and ensure expandability. These “backbone” cables are usually laid securely in cable trays or ducts. However, for larger, moving components the backbone often has to be routed using drag chains. To meet these requirements, Lapp has developed its ETHERLINE® Cat.6A FD cables. They are suitable for drag chain use and guarantee reliable data transmission of up to 10 Gbit/s over several million bending cycles. These ETHERLINE® cables are flexible and improve your total cost of ownership with faster installation and lower downtime. With ETHERLINE® Cat.6A, LAPP recommends the use of M12 connectors where water-tightness and dirt resistance in accordance with IP67 are required.

LAPP also offers space-saving yet robust solutions such as the 30% thinner ETHERLINE® EC, suitable for use at sensor level which allows the tightest bending radii. Thanks to the robust PUR outer sheath, the cable can also be used with high mechanical stresses or in oily environments. Another extension to the ETHERLINE® products is the robust 4-wire Cat. 5e Ethernet® cables. These are also available as finished products with a pointed, space-saving M8 connector that is substantially smaller than the M12 connector, commonly used with Industrial Ethernet. Building on this innovation, we will be launching ETHERLINE® ACCESS, the managed and unmanaged switches at the Automation Expo’17.The switches along with data cables and connectors form Lapp’s offering for the industrial network solutions to ensure reliable connectivity for the smart factories of the future.

To meet the requirement of manufacturing machinery for slim and robust cables, Lapp has ETHERLINE® EC cables. Generally core 4 Cat 5 cables are used in these machineries. The Cat.5 Ethernet cables that are available today often need too much space because of their large outer diameter and bending radii. Either the machine has to be built larger, or the cable has to be installed without the necessary bending radius specified for installation. This can result in damage to the cables and to failure. Lapp has developed for these applications ETHERLINE® EC cables. The 4-core Cat. 5e Ethernet cables are only 5 mm thick and allow a small minimum bending radius of just 16 mm. The compact ETHERLINE® EC cables and the M8 connector are also available as an extremely robust assembly which fulfils the permeability standards set out in IP67.

With the demand for fast and secure communication network constantly growing, fibre optic cables are now an indispensable and irreplaceable communication medium. Lapp offers HITRONIC® cables (GOF, POF & PCF) which have the benefit of insensitivity to electromagnetic interference low attenuation values, large transmission distances and high bandwidths and are light in weight with compact dimensions and high level of interception production. These cables can be used for all kind of industrial products solution especially for drag chain, torsion, break out and aerial application for Indoor and Outdoor installation.

Industry 4.0 is becoming more and more of a reality. Plug-and-produce products provide the flexibility, modularity and field level control needed to equip the smart factory of tomorrow. The future industries will have innovative machines and plants that can be retrofitted to increase the production efficiency. Reliable networking of production across all levels is only possible with a comprehensive cabling and connection concept. Hence cables and connection will have a critical role to play in the Smart factory which is seen as a turning point in the industrial production