“Despite Clifford being a niche player in the industry, we are constantly boxing above our weight division as we bring new products and innovative ideas to our range which often we see being copied by our competitors,” says Mr. Iain Ambler, Technical Director, Clifford Machines & Technology.

Clifford Machines & Technology (PTY) LTD have, throughout their long standing history, prided themselves in the strides they make in improving and innovating production methods and machinery for the wire mesh industry, by putting reliability of machinery and quality of product first and foremost. It is this drive for quality and reliability that has led to many of its advancements in the welded wire mesh industry and the products it produces. Mr. Iain Ambler, Technical Director, Clifford Machines & Technology, says, “Despite Clifford being a niche player in the industry, we are constantly boxing above our weight division as we bring new products and innovative ideas to our range which often we see being copied by our competitors”. When asked why Clifford does not legally protect its intellectual property, Chief Executive Officer, Mr Craig Markham, advised that “ultimately we concentrate our resources on producing world class products rather than engaging in legal games and we consider imitation a great form of flattery!”

Clifford Machines & Technology (PTY) LTD have, throughout their long standing history, prided themselves in the strides they make in improving and innovating production methods and machinery for the wire mesh industry, by putting reliability of machinery and quality of product first and foremost. It is this drive for quality and reliability that has led to many of its advancements in the welded wire mesh industry and the products it produces. Mr. Iain Ambler, Technical Director, Clifford Machines & Technology, says, “Despite Clifford being a niche player in the industry, we are constantly boxing above our weight division as we bring new products and innovative ideas to our range which often we see being copied by our competitors”. When asked why Clifford does not legally protect its intellectual property, Chief Executive Officer, Mr Craig Markham, advised that “ultimately we concentrate our resources on producing world class products rather than engaging in legal games and we consider imitation a great form of flattery!”

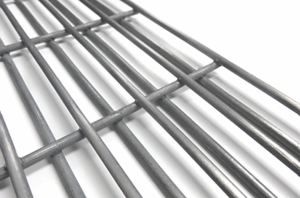

With this continual need to push for innovation, Clifford has recently designed, manufactured and successfully commissioned two new wire mesh fencing machines, for a major international supplier of welded mesh fencing products which boast unique features allowing the customer to produce an entirely new and unique range of weldmesh fencing. These wire fence machines boast product flexibility, reliability and quality without compromising speed of production.

To produce welded wire products that meet production demands is a feat in itself, but Clifford, using advancements in the crosswire pre-tensioning system, have a multi-height tensioning system to allow tensioning to take place at different heights. This system coupled with Clifford’s direct welding heads has made it possible to produce perfectly flat welded wire mesh while still maintaining the stream of production, allowing both quality and production targets to be met efficiently. These particular welded wire fencing machines have numerous advances but one in particular is production of fencing with of both over and under crosswires. This in itself is not a particularly new technology but Clifford has also made it possible with different wire diameters and with under and over cross wires at different pitches to each other which can also be flush trimmed to the outside line wires – truly a world first. This allows the client flexibility to produce various products, with minimal setup changes. The ability to quickly change between products makes these machines as flexible and versatile as the ever changing wire industry market place.

There is always a fine balance that every industrialist faces between product quality on one side, and production speed on the other. Clifford’s advancements have created a synergy between both quality and production speeds and where Clifford has innovated, others are sure to follow! Clifford Machines & Technology (PTY) Ltd. has yet again proven they are capable of setting the precedent within the welded wire mesh machinery industry.