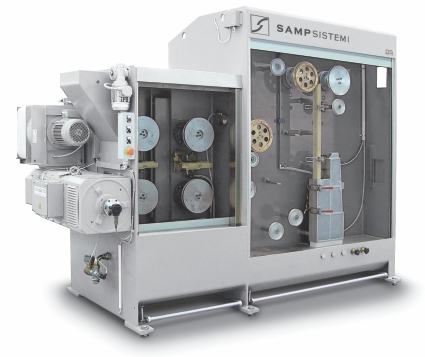

Sampsistemi along with its service division C2S, provide solutions for three major business sectors that include drawing, extrusion and rotating equipment.

Sampsistemi and its service division C2S are equipped to manage the reconditioning or revamping of a machine, line or electrical cabinet, thanks to their knowledgeable department for machine modernization, thus enabling customers to increase equipment reliability and minimize costs with a guaranteed result.

Our expertise ranges across 3 main business sectors: Drawing, extrusion and rotating equipment.

The advantages of revamping in comparison to a new purchase are, obviously, lower costs (usually 50% less) as well as shorter delivery times (usually by 60%) in the case of machines and lines that have been used respecting the original maintenance and operating instructions.

- The main advantages of a retrofit, upgrade and rebuilding made by Sampsistemi and C2S are

- Maximum expertise in machines and relative technology

- Technical documentation for rebuilding and reconditioning parts

- A smart and proactive stock of thousands of items, ready for shipment, for all brands

- Technical validation of the components that have been replaced

The rebuilding procedure begins with a C2S engineer inspecting the machine or the line at the customer’s site. During the inspection, the technician can see the machine in operation (whenever possible) and, based on customer information and know-how, define if a complete reconditioning is needed or if only some parts must be replaced to restore the original quality and technical efficiency of the machine.

When the rebuilding takes place at our facilities, machines are completely dismantled, cleaned and stripped of their paint. This allows us to completely clean the pipes and check if the frame and tanks are in good conditions or corroded. Afterwards, technicians take care of the full substitution of all the damaged components, aiming to maintain performances and restore productivity of all production lines by implementing up-to-date technologies.

As regards electrical cabinets of industrial machineries, the best solution is often a complete modernization of drives and PLC systems according to the latest technology, including the Field bus communication and a new HMI. Our engineers provide customers with a wide range of solutions and technical skills for the upgrade of electrical cabinets and control systems.