The Bremen-headquartered company offers innovative technologies for quality control in cable extrusion, optical fiber drawing and for plastic pellet inspection.

SIKORA AG is a leading manufacturer and supplier of innovative measuring, control, inspection, analysis and sorting technologies for the wire and cable, hose and tube, sheets, metals, optical fiber and plastics industries. Worldwide, users of the measuring devices benefit from increased product quality, profitability and efficiency of the manufacturing process.

Comprehensive product portfolio for diverse applications

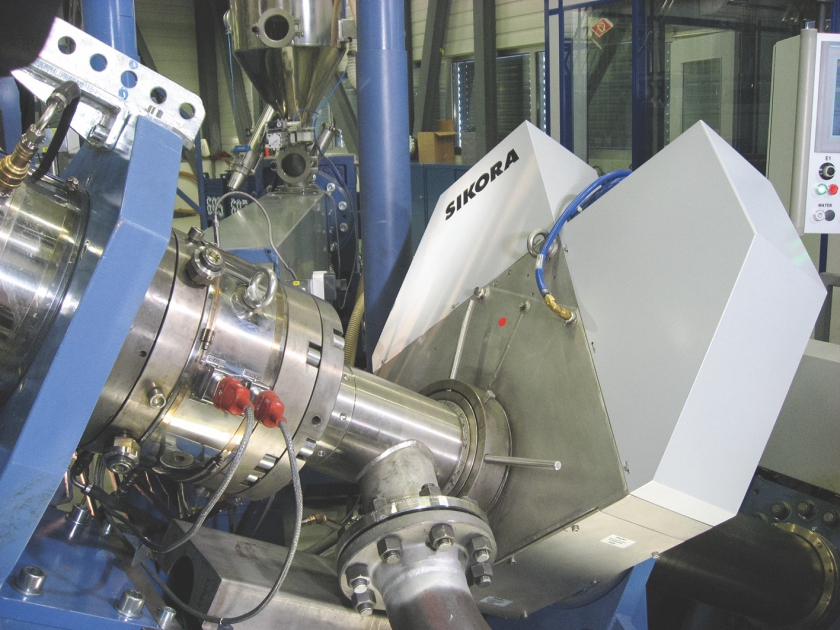

Modern Laser and X-ray technologies measure precisely and reliably product parameters such as outer diameter, ovality, wall thickness and concentricity. In addition, SIKORA’s product portfolio comprises spark testers for the detection of insulation faults, lump detectors for the detection of faults on the product surface, capacity measuring systems as well as devices for reliable conductor preheating and temperature measurement and control. The application areas are diverse. SIKORA technologies are for example installed in extrusion lines for quality control of automotive and data cables as well as building wires. Also in insulating and sheathing lines as well as for measuring and controlling high voltage cables in CV-lines the SIKORA systems are predestined.

Continuous control of production data helps to avoid wall thickness oversizes and allows for a more efficient and sustainable material usage. Every micrometer of material that can be saved by the use of measuring and control technology makes the production more economical and saves increasingly scarce resources.

Quality control of optical fibers in the drawing tower

SIKORA also offers a wide range of measuring systems for quality control of optical fibers at different positions in the drawing tower. It consists of devices for the measurement of the diameter and the position of the bare and coated fiber as well as for the determination of the tension and detection of airlines. Further gauge heads measure the fiber temperature at the hot position to determine the fiber temperature for the control of the furnace, and at the cold end, to exactly dose the helium used for the cooling. In addition, a gauge head for the determination of the concentricity of the coating as well as for the detection of lumps on the surface of the coated fiber is available.

Inspection, analysis and sorting technologies for highest plastic pellet quality

SIKORA also provides online and offline inspection, sorting and analysis systems for plastic pellets as they are used e.g. for the insulation of medium, high and extra-high voltage cables. The PURITY SCANNER ADVANCED is an online inspection and sorting system based on X-ray and optical technologies. Contamination inside the pellets as well as on their surface are detected and automatically sorted out. SIKORA also offers offline inspection and analysis systems such as the PURITY CONCEPT X, based on X-ray technology. It detects and analyzes e.g. metallic contamination both on the surface and inside of colored pellets. By using inspection, sorting and analysis systems, contamination can be excluded, breakdowns of a cable eliminated and material costs saved. Besides economic advantages, the environment can be preserved due to less waste.

SIKORA solutions – Made in Germany and globally in use

SIKORA is headquartered in Bremen, Germany. Since 1973, the high-quality devices have been developed and manufactured at this site. When it comes to service and sales, SIKORA is globally active with offices in Brazil, China, France, India, Italy, Japan, Korea, Malaysia, Mexico, Russia, Turkey, Ukraine, the United Arab Emirates and the USA. In cooperation with more than 30 local representatives worldwide, SIKORA serves all customer demands for optimum quality control and productivity. In addition, international service locations ensure fast and reliable customer support on site, any time.

Since 1993, SIKORA has been meeting the requirements of DIN EN ISO 9001. The certification confirms SIKORA’s focus on continuous improvement. Customer satisfaction is SIKORA’s primary objective. Innovation, technological know-how, experience, quality and service are the five pillars of SIKORA’s company philosophy. A strong research and development team continuously works on the development of new technologies, enabling manufacturers to optimize product quality and production processes as well as efficiency and the ecological balance of their production lines.