November 25, 2014

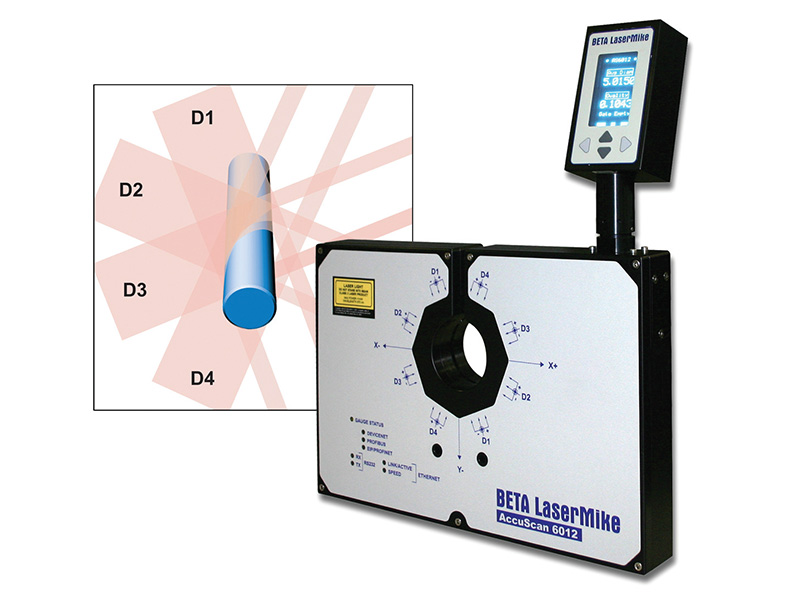

NDC Technologies introduced the industry’s first four-axis 12 mm diameter gauge with up to 100% ovality accuracy for critical communication cable applications. The new Beta LaserMike AccuScan 6012 gauge delivers higher diameter and ovality measurement accuracy over two- and three-axis gauges for increased performance, quality, and savings. It is built on the proven and widely deployed AccuScan series platform for measuring products up to 12 mm.

Usually, two-and three-axis diameter and ovality gauges have been used by high communication cable manufacturers for online and offline measurement applications. But, with increasing production line speeds the precise measurement is quite challenging. Any error in the diameter or roundness of the conductor or insulation in Coaxial and twisted-pair LAN products directly impacts the cable’s performance characteristics — rendering it useless for the designed application.

The new Beta LaserMike AccuScan 6012 four-axis gauge overcomes the problem with more comprehensive measurement coverage and an ultra-fast scan rate.

AccuScan 6012 Four-Axis Product Highlights:

• Accurate Average Diameter: The AccuScan 6012 performs ultra-fast measurements at 2400 scans per second per axis (totaling 9600 measurements per second) and provides the highest single-scan accuracy in the industry with single-scan repeatability to 1 micron. This means with each and every scan you get a true and more accurate average diameter measurement

• Improvement in Ovality Accuracy: The AccuScan 6012 offers a 42 percent improvement in detecting true ovality over three-axis gauges and delivers 100 percent ovality accuracy when the product is aligned with the measurement axes

• Highest Flaw Detection Accuracy: The AccuScan 6012 provides the highest flaw detection accuracy with 25 percent improvement over 3-axis gauges. The ultra-fast scan rate and higher accuracy coupled with the High-Speed Tolerance Checking option permits the early, accurate, and dependable detection of product flaws such as lumps and neckdowns. This enables manufacturers to better control product quality, reduce scrap, and realize manufacturing savings

• High-Accuracy Offline Part/Sample Inspection: Using the Beta LaserMike PC-based AccuNet display system, the AccuScan 6012 can be easily and quickly setup as an off-line part measurement system to check samples and track, manage, and analyze critical product data. This eliminates the need to set up two dual-axis gauges to perform four-axis measurements

NDC Technologies is a global organization involved in the innovation, design, and manufacture of precision measurement and control systems for a wide range of industries.