With over 65 percent market share in domestic market and a comprehensive range of over 250 spools, Vikas Spool is always looking for new developments and associations to augment its product range in sync with time; the new association with Italian company New Spool is but one step in that direction.

Vikas Spool Private Limited (VSPL), India’s largest plastic and metal spools manufacturing company for wire and cable industry, started manufacturing spools in the year 1992. The company makes dispatch and process spools for copper wire & strip, stainless & mild steel wire, aluminum wire, welding wire, special purpose wires, cables and yarn.

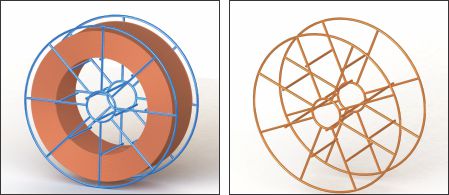

Vikas Spool has recently forged an alliance with New Spool Srl of Italy, a producer of wire basket spools and spool manufacturing machines for the welding wires. Vikas Spool has shown keen interest in these spools and plans to understand the current fundamentals and then educate the Indian welding wire industry of its advantages. WCI recently had a brief interaction with Mr. Vikas Yadav, Director, VSPL and Ms. Cristina Salazer, Sales Manager, New Spool. Excerpts:

Wire & Cable India: To start with, tell us something about your company.

Vikas Yadav: We had a humble beginning in 1985 as a trading firm for spools. Our first micro scale manufacturing facility began operations in 1992 in 100 sqm premises. Today, as India’s largest plastic and metal spool manufacturing company in, we cater over 65 percent of Indian market’s spools’ requirement. Currently, we operate in a total of 12,000 sqm facility with 40 injection molding machines and over 200 different moulds. With over 30 years of experience, state-of-the-art machinery and fully equipped test lab, we strive to provide complete customer satisfaction through quality products and services.

WCI: What is your future plan regarding your association with New Spool?

WCI: What is your future plan regarding your association with New Spool?

VY: New Spool offers steel spools for welding wire industry. Our association with them is in line with our long-term agenda of providing as much environment friendly packaging solutions to our customers as possible. Like plastic, these spools are 100 percent recyclable. However, unlike plastic, steel does not lose its strength after recycling. This means a better scrap value for steel spools, which we believe will be a financial incentive for end-user of welding wire to purchase wire on these spools.

After use, plastic spools end up being thrown away for a very low price. After reprocessing, these end up into an inferior quality of plastic, and it is not as environment friendly as steel. With use of steel spools, even without a conscious effort, our customers and end-users are certainly going to contribute in a big way towards a greener and cleaner tomorrow. And let me reiterate that this is a long-term objective – maybe 5-6 years down the line, we will see this happening. For us, like year 1985, I think it is another humble start.

In terms of operations, in this association, VSPL will be taking care of domestic distribution as of now and New Spool will continue to make this product in Italy. A bigger task at hand is to educate the customers and end-users about the product, its advantages and also understand their concerns. It’s going to be a big challenge to convince a small-scale welder or a big corporation; to not to use what has been used in market for over last 30 years. I think this is the right strategy for next 2-4 years before we actually set up a manufacturing facility here in India.

WCI: So, essentially, as of now, your association with New Spool is more about spreading awareness about the advantages of steel spools than doing any substantial business, isn’t it?

VY: That’s Correct! We will be importing these spools for a while and distributing these in the industry till a time where they start accepting it as a better spool. Few Indian companies already import these spools but they mostly import these for their export requirement. As of now, hardly 2 percent requirement of the domestic market is being served on these spools.

But we want to change the game and want everyone to switch to these spools for better, in all regards. There is more precision in layer winding, you get more spools per hour, you save cost with higher scrap value, and then most importantly there are less breakages. We are aware that in B2B space all businesses are price-sensitive. We are trying to match the price of plastic spool by offering them a better value for money.

WCI: As I infer, the association is a long-term one and the real manufacturing would happen after 5-6 years, isn’t it? What will be you doing in the meanwhile?

Cristina Salazer: Yes, our association has been conceived as long one. For the moment, we would be sending him (Vikas) the container with the material so that he can fulfill the requests of the market and satisfy those clients who don’t need one big container but may be just couple of pallets at a time. So, instead of having to buy the whole container from us, and therefore working capital getting stuck and spools getting worn out, the client can have this benefit of buying it in the Indian market and buying just the quantity that he needs with a shorter lead time.

WCI: How did you come to this decision to do a joint venture with Vikas Spool?

CS: We met few years back and started working on this idea as he was in the field of making spools. Vikas Spool didn’t have these spools but we did. And we wanted to go to the Indian market, which Vikas Spool has best access to. From Italy to India, transport costs are very high and are the biggest challenge for us while selling spools. So, we suggested that let’s try and work together and with our collaborative effort we could create something good in long run.

WCI: Is it right that New Spool makes spool making machines also? Which one happened first,the spool or the machine?

CS: The mother company was in Sweden and they started making spools. Because it was the request from Sandvik, also this spool is sometimes called the Sandvik Spool. The mother company started making the machines and selling the spools. We bought these machines from them in 1998 and started producing spools. After that, in 2009, the company in Sweden had to close and we decided to buy everything from them and start making machines. We have improved the original design significantly since then.

WCI: What are New Spool’s expectations from Indian market 4-5 years down the line?

CS: Well, we hope that we will be able to substitute the plastic spools and just be able to start the production here in India.

WCI: If you talk about substituting plastic spools, won’t you be substituting most spools used by the wire and cable industry presently?

VY: Well, not really! We make plastic spools for all sorts of wires – copper, ss, ms, and aluminum etc. but this spool is specifically designed for welding wire. Of overall wire industry, welding is around 8 to 12 percent. Wire basket spools from New Spool can only substitute plastic spools for welding wire and not others.

The consumption of steel per capita in India is very low as compared to developed nations. Whenever there is going to be an increase in consumption of steel, there is going to be an increase in demand for welding wire. If things go well for Indian Infrastructure, which we are almost certain of, welding wires will end up forming a bigger share of overall Indian wire industry.

Now with respect to spools, this increased consumption, would mean – increase in demand for spools. In this increased demand, we intend to have a larger share for wire basket spools.

WCI: Anything else that you want to add with regards to the Indian wire and cable market?

CS: The first thing is that the metallic spool BS300 that New Spool makes is more rigid and more precise with respect to plastic spools; so, that would be the first reason that it would give you a better quality. The second reason would be the capacity of wire that you can wind up is 15-20 kg. The third is addressing the environment and plastic is certainly not environment friendly whereas BS is environment-friendly spool. As a bonus, when you have to scrap it out, you get money back from it.

VY: In line with what just Cristina said, it is important to note that in plastic spools you could wind only 15 kg of wire; ideally they do 12.5 Kg only. But in metallic spools, just by changing the barrel diameter and still keeping the price same, we can offer customers the option of 15 kg, 18 kg and 22 kg; we are also experimenting with 27 kg now. So, the spool price remains same and customer gets a lower per kg packaging cost.

Besides focusing solely on financial statements, our long-term vision is a great deal about ethical entrepreneurship, about being an ethical industrialist. VSPL is the largest plastic spool manufacturer in India. I certainly want our company to be seen as the most responsible manufacturer by all its stakeholders; and that includes our society, our environment.

Tomorrow, I would really like to do everything that we do, in a more environment-friendly manner than today. Global innovators of spools have been able to create a perfect substitute for welding wire spools only. So we can certainly start there.

I would like our country, India and every Indian to play an active role in everything big or small that has to do with environment. If we can do this (replacing plastic spools with metallic ones) in the next 5 to 7 years, it will be a great contribution to the world, by entire industry.