The limitations of the conventional LAN cable and optical fiber can be eliminated with a simple change in the material of the insulation. LAN cables insulated with Fluorinated Ethylene Propylene (FEP) warrant a Velocity of Propagation (VoP) of 90 percent and a much higher lifespan. FEP is a fluoropolymer that has extremely good chemical and thermal properties. By using FEP we can achieve a higher transmission performance.

Under the Digital India campaign and the government’s vision of making India a USD 3 trillion digital economy, India is moving towards having greater connectivity and a higher emphasis on security. Advanced applications such as Fast Ethernet, ATM and Gigabit Ethernet require more efficient systems so that cabling systems can reliably transfer voice, video and data information.

LAN cables are of paramount importance in this scenario. In a data transmission circuit, the effective velocity of propagation and transmission speed depends on the weakest link in the route. Ergo, the cables employed in between, assumes a lot of importance.

Various categories of LAN cables are available on the market, such as CAT 5, CAT 5e, CAT 6, CAT 6a, CAT 7, etc. CAT 6 with a recommended single length of 50m at 250MHz is currently regarded as the most efficient cable. For demanding applications like high-definition video and audio streaming and high-speed Internet, CAT 6a or CAT 7 cables are usually used. These cables offer bandwidths of 250MHz and 600MHz respectively for the recommended length of 100m, which confers a limited VoP of around 66 percent.

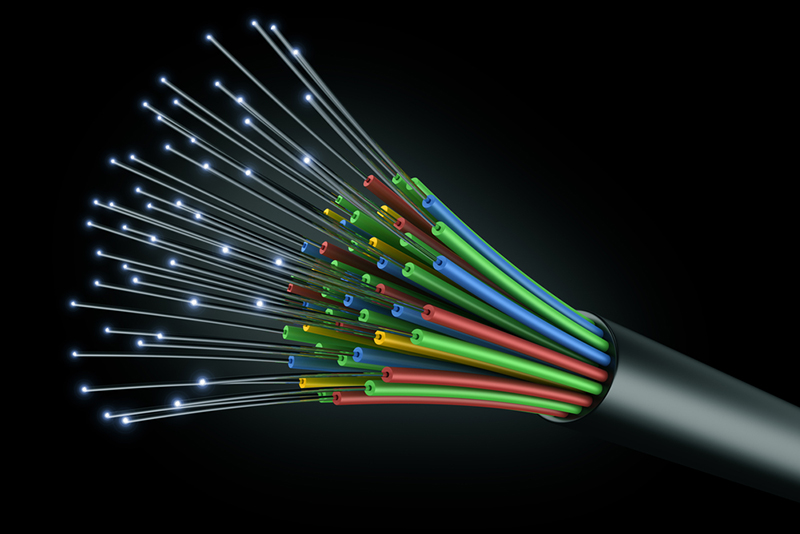

However, for a higher bandwidth these LAN cables virtually become inefficient and the end user switches to optical fiber cables. Conventional optical fiber cables, though offering a higher bandwidth, have drawbacks like higher cost and low velocity of propagation (67 percent). In addition, they have connectors that are more prone to damage than copper connectors used in LAN cables.

When it comes to high-performance applications, even the conventional CAT 7 cables made with HDPE insulation, do not perform impressively at a relatively lower bandwidth of 600 MHz. Large bend radius and the high thickness of the insulation limit the commercial viability of the product as well. The aforementioned limitations of conventional LAN cable and optical fiber can be eliminated with a simple change in the material of the insulation.

LAN cables insulated with Fluorinated Ethylene Propylene (FEP) warrant a VoP of a whopping 90% and have a much higher lifespan. Modified FEP has a dielectric constant of less than 1.5 that ensures minimum attenuation losses and eliminates crosstalk. Also, the thickness of the LAN cable required is lower than polyethylene, which further ensures low bend radius of the product and makes installation of the cables easier.

Besides, FEP, being a fluoropolymer, has extremely good chemical and thermal properties. Because of its superior thermal performance, it is recommended by USA’s fire protection standard NFPA 262 & UL 910 as the most efficient material for LAN cables insulation used for plenum spaces as per the 1987 National Electrical Code Hierarchy. The thermal resistance properties of the product keep the cable from burning and prevent potential damage making it virtually a fire-proof material.

Independent research shows that the dielectric losses increase in data cables significantly beyond 1GHz when the insulation applied is HDPE. The propagation loss observed is of about 2.6th power of frequency that results in the deterioration of signal throughout the cable. By using FEP we can eliminate this fundamental problem of LAN cables and thus achieve a higher transmission performance. Due to its exceptional performance and thermal properties, FEP-based LAN cables capture a significant share on US markets.

Also, fluoropolymer, owing to their extremely good thermal, chemical and dielectric properties, are being used in many other important areas. For instance, fluoropolymer-based submersible pump winding wires are manufactured by a few processors that can withstand voltages up to 15KV and provide much more longevity and reliability than the conventional wires. FEP is also used in Power over Ethernet cables, which are required to maintain performance even at higher temperatures where conventional insulation materials tend to fail. Fluoropolymer insulated wires are also finding acceptance in various housing and industrial applications.

Written by:

Pranjal Pathak, Gujarat Fluorochemicals Ltd.