A number of forward-thinking cable makers, along with major utilities worldwide, are already producing and testing polypropylene-based insulation systems (PPC) for MV and HV applications, both in AC and DC.

March 18, 2020

PPC systems are characterized by excellent properties: lower carbon footprint, no degassing needed, no byproducts, recyclable, equal or better electrical properties, higher operating temperature, to name just a few. These cables can also be installed in the XLPE-based network using the same accessories as XLPE cables.

Medium-voltage AC cable properties with RoSET

Rosendahl conducted both internal and test institute tests, which reveal excellent electrical performance at both the AC breakdown and impulse tests. The successfully passed full electrical type test also showed very low loss factor (Tan Delta) values, even when compared to the so-called reference peroxide XLPE grade.

What is Rosendahl actually comparing? Their new RoSET insulation system is tailored to MV cable production. Therefore, it should be compared to similar kinds of grades. Quite often these are water-tree retardant XLPE compounds with different properties than HV/EHV XLPE grades. As is well known, the thermal conductivity of pure polypropylene is much lower than that of polyethylene. With polypropylene copolymers, however, the difference is no longer so great.

Together with their development partner HV Cable Solutions, they made some ampacity calculations with different XLPE and PPC grades for a single 20 kV cable. The results showed that the polypropylene compound cable can have better current carrying capacity, transmission capacity and lower electrical losses at 90° C and that the cable can also be run at 110° C, if necessary. This was also the case in auxiliary tests when a similar MV XLPE cable was compared to a MV PPC cable.

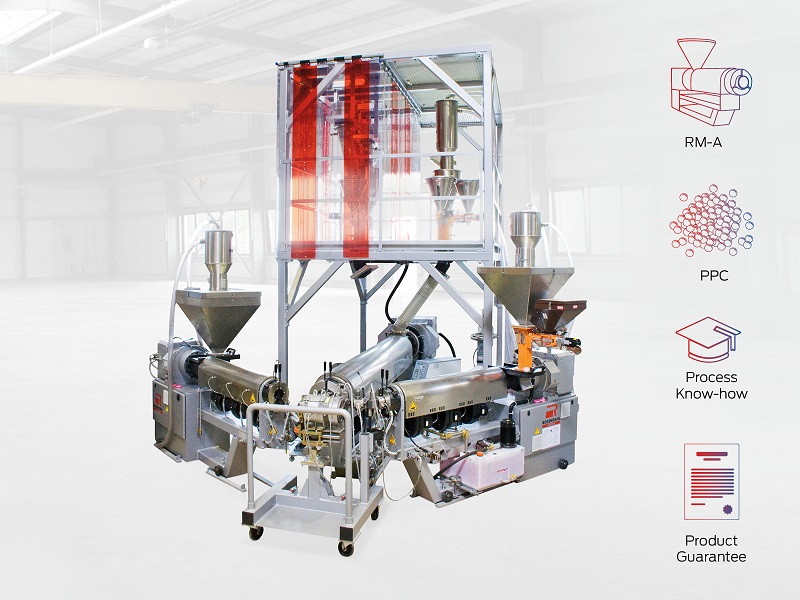

Does one need a dedicated production line for PPC?

Rosendahl has extensively tested RoSET MV PPC in their laboratory in Pischelsdorf and also with complete production runs on an installed line. Over the past 18 months they have had a dedicated extrusion setting for the RoSET insulation system compounds with high and stable performances.

During the real cable runs, they also found that they had to advise cable producers to take care of cross contamination when changing from one material to another and to be particularly careful when handling the materials in general. On this basis, a special material handling system has been developed. Rosendahl strongly recommend a dedicated horizontal MV PPC insulation line to avoid any problems and to ensure successful test and production runs to serve the forerunners on the market with a best available quality. As the PPC technology develops towards higher voltages and different properties, Rosendahl will continue to be part of that development.