We are planning to invest around INR 50 crore for the expansion and modernization of our various units and also, our focus will be to venture into the tyre-bead wire segment.

Wire & Cable India interviewed Mr. Sampath Gilada, Managing Partner, Gita Group, wherein he dives into the business story of the Company, the applications of their product range, the details about the manufacturing facility, and the future aspirations of the Company.

Wire & Cable India: Could you please walk us through the overview of Gita Group and the product range offered in the wires segment?

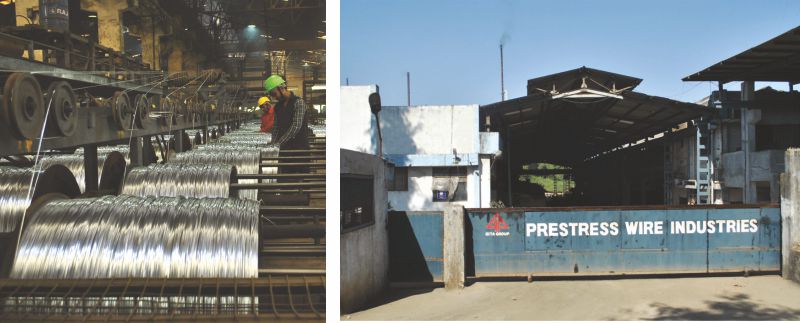

Sampath Gilada: Gita Group was established in the early 1960s by – Gilada and Tapadiya families in Karnataka. The Group has four PC, galvanized and allied products and wire manufacturing units located in Silvassa (Dadra & Nagra Haveli), Bajpur (Uttarakhand) and Bangalore (Karnataka).

In addition, the group also has seven sleeper units in India and two units in Africa. We also have seven PC pole manufacturing units, five pulses units, besides having a distinct infrastructure division dedicated towards water supply and road projects. Further, we have our presence in segments such as – real estate, power generation, refractory manufacturing, and ductile engineering castings for railways and automobiles with the global turnover of IRS 850 crore in FY 2020-21.

Prestress Steel LLP (formerly known as Prestress Wire Industries) had started during the year 1994 with the capacity of 3,500 MTPA and now, the company has grown to reach the annual production capacity of 80,000 MT with its four distinct manufacturing plants. The Company has a diverse range of products such as – single and stranded PC wire, ACSR core and stranded wire, special ACSR wire with 19 wire strand, earth wire, commercial galvanized, nail wire, screw wire, spring steel like bedding and shutter wires, as well as bailing wire luggage spring. Our PC wires and ACSR wires are exported to the Middle East, Bangladesh, Turkey, Africa, and European markets on a regular basis.

We were able to sell 70,000 MT of wires of various grades and sizes in the FY 2020-21, amidst a very challenging COVID-19 pandemic situation.

WCI: Kindly share some details about the applications of these prestressed steel wires and the features of these wires regarding their performance.

SG: These wires are used in a number of applications including – the prestressed railway sleepers, electrical poles, aluminum conductor manufacturing, bedding, soft luggage, high tensile nail manufacturing and screws.

Also, we can manufacture single indented PC wire in the range of 3.0mm to 10mm.

WCI: Please describe the manufacturing facility and the production capacity of the Company of the wires segment – both alloy and non-alloy wires. Could you please talk about the market-reach of the Company?

SG: Each of our manufacturing units are state-of-the-art, having high capacity in straight line wire drawing manufacturing, along with galvanized wire pad wiping facility and eco-friendly pickling and furnaces. All of the units are ISO 14001, OHSAS & BIS-approved, ensuring the satisfaction of our customers with respect to the quality of the products.

At present, we are operating in the Northern, Southern and Western region in India and moving forward, we are looking to establish our presence in the Eastern region as well.

We are looking forward to catering to the East-Indian market as we are intending to set up a manufacturing facility in Odisha.

WCI: How has the growth been for the company in the past year and in the future years, what would be your expectations for the further growth of the Company? Going ahead, what are the plans of the Company and what will be your major strategies to strengthen your positioning in the market?

SG: We were able to sell 70,000 MT of wires of various grades and sizes in the FY 2020-21, amidst a very challenging COVID-19 pandemic situation. At present, we are planning to invest around INR 50 crore for the expansion and modernization of our various units and also, our focus will be to venture into the tyre-bead wire segment.

Further, we are looking forward to catering to the East-Indian market as we are intending to set up a manufacturing facility in Odisha