RR Kabel is developing advanced insulation and sheathing formulations- it operates an in-house EBXL line along with automated quality control systems to ensure its solar cables perform reliably even under harsh conditions. In an exclusive interview with Wire & Cable India, Mr. Shreegopal Kabra, Promoter and President of RR Global, highlighted how RR Kabel’s adherence to AD8 compliance sets its solar cables apart—making them suitable for continuous submersion in water, a critical requirement for floating solar installations. Additionally, RR Kabel has introduced DC solar cables with enhanced insulation and high-grade thermal stability, ensuring long-term reliability under demanding high-voltage conditions.

Wire & Cable India: As India increasingly adopts 1.5 kV DC system architecture in large-scale solar installations to reduce BOS costs and improve system efficiency, how has your company adapted its solar cable design, especially in terms of insulation, thermal performance, and long-term reliability?

Shreegopal Kabra: As India increasingly adopts 1.5 kV DC systems for large-scale solar installations, we have proactively upgraded our cable designs to meet these new demands.

Our latest DC solar cables incorporate enhanced insulation and superior thermal stability, delivering exceptional long-term reliability even under high-voltage conditions.

Our products conform to IS 17293, India’s governing standard for solar DC cables, while also aligning with international benchmarks like EN 50618 and IEC 62930.

We’ve invested in developing advanced formulations that maintain insulation and sheathing integrity at elevated temperatures. Our designs also account for UV exposure, thermal cycling, and mechanical flexibility required in utility-scale installations.

We ensure our cables maintain peak performance throughout their 25+ year service life, making it ideal for India’s aggressive solar deployment goals.

Watch: Top Cable Companies in India

WCI: What role does electron beam (e-beam) cross-linking technology play in your solar cable manufacturing, and how does it compare to conventional cross-linking methods in terms of performance and cost-efficiency?

SK: Electron beam (e-beam) cross-linking has become a cornerstone of our cable manufacturing process. Unlike conventional methods, e-beam technology achieves crosslinking at the molecular level using high-energy electrons that enables uniform cross-linking of polymers throughout both insulation and sheath layers, delivering outstanding thermal, mechanical, and UV resistance even under prolonged outdoor harsh conditions.

This process eliminates risks of under or over-curing, guaranteeing consistent product quality. Although the initial investment is higher, e-beam cables offer unparalleled longevity and cost-efficiency over the project’s lifetime, particularly when deployed in demanding outdoor environments.

WCI: With floating solar and hybrid solar-plus-storage systems on the rise, how are your cables engineered to handle environmental extremes like water submersion, high UV exposure, or EMI interference?

SK: At RR Kabel, we have specifically designed solar cables for challenging environments like floating solar parks or hybrid solar plus storage systems, by incorporating high-grade, water-resistant and UV stabilized insulation compounds. These materials retain mechanical strength, flexibility, and insulation resistance even in submerged or damp conditions over extended lifecycles.

A key differentiator in our offering is our adherence to AD8 compliance, which signifies suitability for continuous submersion in water which is a crucial requirement for floating solar installations. Our cables undergo rigorous testing for water absorption, submersion endurance, and UV aging in line with both IS 17293 and international standards like EN 50618 & IEC 62930.

WCI: Can you walk us through your quality assurance processes, especially with respect to BIS compliance, fire safety, and lifecycle testing under IS or IEC standards?

SK: Quality assurance is embedded in every phase of our cable manufacturing, from raw material inspection to final delivery. We conduct routine, type, and acceptance testing, on every batch manufactured at RR Kabel.

All our solar cables are manufactured in compliance with IS 17293, the BIS-mandated standard, and tested under the protocols laid out in the IS 10810 series and relevant IEC methods.

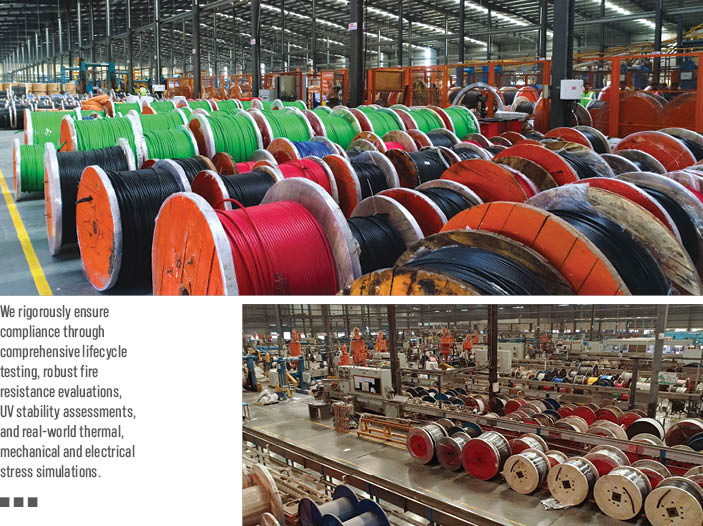

We rigorously ensure compliance through comprehensive lifecycle testing, robust fire resistance evaluations, UV stability assessments, and real-world thermal, mechanical and electrical stress simulations.

Every cable undergoes 100% in-line spark and high-voltage testing, further reinforced by accelerated aging tests, guaranteeing long-term safety, reliability, and performance for our customers. Further, every batch is digitally logged, making our traceability and documentation process seamless for audits, certifications, and exports.

WCI: What raw material trends are you observing, particularly in conductor metals and insulation compounds? How are you balancing performance with price volatility?

SK: We are seeing a growing trend toward high-conductivity copper and advanced halogen-free, flame-retardant compounds for insulation and sheathing.

In response to fluctuating global copper prices, we maintain a diversified sourcing strategy and invest in ongoing R&D to enhance material efficiency while maintaining superior performance.

RR Kabel leverages its backward integration in polymer manufacturing, enabling both material consistency and cost control. Through continuous design optimization, we ensure cost-effectiveness for our end-users without sacrificing quality or reliability.

Every cable undergoes 100% in-line spark and high-voltage testing, reinforced by accelerated aging tests, guaranteeing long-term safety, reliability, and performance for our customers.

WCI: Are you seeing increased traction from global EPCs or exports for Indian-made solar cables? If yes, what benchmarks or certifications are most demanded internationally?

SK: There is increasing demand from global EPCs and export markets for Indian-manufactured solar cables. Internationally recognized certifications such as IEC 62930 and EN 50618 along with REACH, RoHS and CE compliance are particularly valued by customers.

Our cables are rigorously benchmarked against these global requirements, ensuring they meet the requirements for export to Europe, Southeast Asia, and Africa. What sets us apart is our ability to meet not just compliance standards but also performance documentation, warranty support, traceability, and life cycle assessment of the products exported, critical for utility-scale projects especially in the export markets.

Our in-house electron beam cross-linked (EBXL) line and automated quality control (QC) systems make us a preferred partner for solar developers who prioritize long-term system uptime, low maintenance, and global compatibility.

Also Read: Polycab Emerges as Global EPC Player Amid Rising Demand for India-Made Solar Cables

WCI: What are the key challenges solar cable manufacturers in India face today: whether it’s certification costs, skilled workforce shortages, or price-driven procurement? How are you tackling them?

SK: The Indian solar cable manufacturing industry is evolving rapidly, but not without facing considerable hurdles.

The key challenges include the rising costs and complexity of obtaining multiple certifications, a limited pool of skilled labour, and the persistence of price-driven procurement mindsets in a highly competitive market. These issues often hinder innovation, compromise product quality, and impact long-term system performance.

Another critical challenge lies in educating both small-scale contractors and large-scale project developers about the importance of adhering to the Government of India’s latest regulations, such as the mandatory use of ISI-marked solar cables under the Quality Control Order (QCO). Despite the government’s clear directive, awareness and compliance remain inconsistent across the value chain.

For quality-conscious companies like ours that invest in aligning with the latest standards, this enforcement lag can be a disadvantage, especially when cheaper, non-compliant products continue to flood the market unchecked.

To address these multifaceted challenges, we have adopted a comprehensive strategy:

Workforce Development: We are building internal capability through structured training programs, ensuring our teams are up to date with evolving technical standards and global best practices.

Process Automation: We have automated key areas of production and quality testing, which not only improves precision but also reduces costs over time.

Industry Collaboration: We work closely with BIS, MNRE, and other regulatory bodies to advocate for stronger implementation of quality standards and to streamline certification processes.

Stakeholder Education: We are actively engaged in educating EPC contractors, consultants, and project developers about the risks of substandard products and the long-term advantages of using certified, high-quality cables. Our goal is to shift the dialogue from initial cost to lifecycle value and reliability.

By addressing both market and regulatory challenges head-on, we aim to raise the overall standard of solar cable adoption in India and pave the way for a more quality-driven ecosystem.

We maintain a diversified sourcing strategy and invest in ongoing R&D to enhance material efficiency while maintaining superior performance.