ZUMBACH Electronic will showcase ODAC® laser diameter and ovality gauge, SIMAC® surface inspection system, QC non-contact, off-line measuring stations, UMAC® CI – a compact, high-tech wall thickness data acquisition system, and RAYEX® S x-ray wall thickness measuring system, shaping the future of production quality and process optimization across a wide range of wire and cable applications.

Feb 02, 2026

ZUMBACH Electronic will once again take center stage at Wire 2026, the premier international wire & cable trade fair, held in Düsseldorf from 13th April 2026.

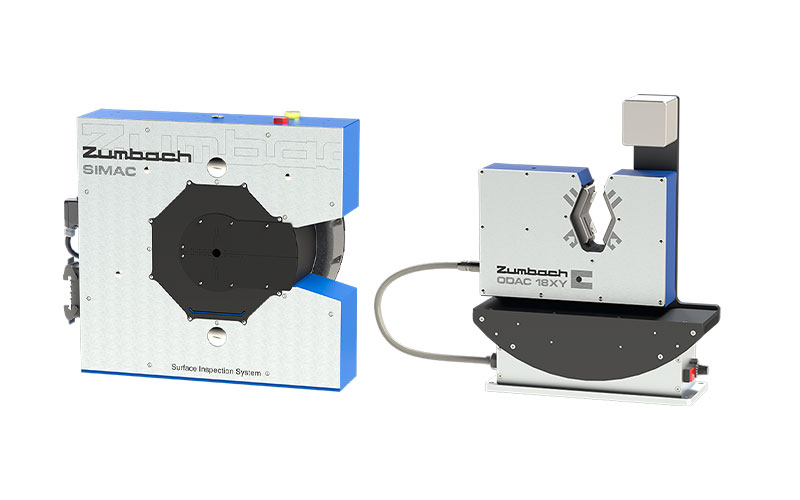

As a world-leading manufacturer of inline measuring systems, Zumbach will be exhibiting the new and improved ODAC® laser diameter and ovality gauges –16 TRIO, 16XY and 18XY models at Wire 2026, packed full of new features including integrated OPC-UA interface, extended defect detection capabilities, FFT, integrated length and speed measurement, and much more. Renowned for precision, over 100,000 ODAC® laser measuring heads have been utilized globally in the past 60 years. They provide the highest non-contact measuring accuracy of diameter, ovality and position for your wire and cable manufacturing. Their excellent price-performance ratio optimizes production costs as well as improving overall product quality, even in the harshest conditions.

The ODAC® laser measuring heads can also be used in conjunction with our DVW and DVO oscillating units – a proven measuring solution for external minimum and maximum product dimensions, typically used to measure height and width, especially useful in the manufacturing of non-round products such as sector cables and flat conductors and busbars.

Watch: Top Cable Companies in India

Apart from that, the company will also exhibit the SIMAC® surface inspection system. The new SIMAC® surface inspection system provides a state-of-the-art solution that utilizes artificial intelligence algorithms to detect and identify material defects and anomalies including colour deviations, cracks, scratches, bruises and surface deviations in general, which would otherwise negatively impact profitability and product reliability.

Along with suitability for use with black surfaces, the new SIMAC® range offers a user-friendly set-up and a selection of other advantages, including defect classification, segmentation and reclassification capabilities. Completing the range, the new SIMAC® 120 enables surface inspection on products up to 108 mm (4.25”) in diameter.

The company will showcase QC non-contact, off-line measuring stations, designed to deliver fast, accurate, and repeatable measurements for wire, cable, and tube samples. These systems combine cutting-edge components to provide unparalleled accuracy and ease of use, ideal for quality control laboratories or factory floors. They offer operators a user-friendly, repeatable solution for measuring outside diameter and ovality, ensuring compliance with exacting specifications and enabling production optimization.

With 4 decades of Ultrasonic measuring experience and expertise, the company has also developed the UMAC® CI – a compact, high-tech wall thickness data acquisition system that comprises a processor and associated sensor. Designed specifically for use in extrusion lines, for measuring and logging wall thickness, eccentricity and other relevant parameters, at a scanning rate of 1000 measurements per second for each transducer.

It utilizes the newest measuring algorithms, offers easy integration and quick setup, as well as providing visualisation of the measurements via the embedded Webserver. The UMAC® utilized in conjunction with the ODAC® and USYS® provides a cutting-edge solution for on-line measurement of the inner conductors and wall of Twinax (duplex) cables that are used in AI supercomputer data centers – a breakthrough that enables cable manufacturers to produce cables of the highest standard required for AI computing.

Lastly, the company will exhibit RAYEX® S x-ray wall thickness measuring system which is an all-in-one solution for measuring wall thickness, ovality, eccentricity and diameter. The RAYEX® S can measure product sizes between 1.5 mm and 100 mm, with wall thickness testing from 0.3 mm. It is a calibratable and certifiable solution that provides automatic control of the line speed or the extruder output capacity, and enables easy product recipe creation.

Also Read: Rosendahl Nextrom Showcase Innovations Across Energy, Mobility and Communication Sectors

Visitors can visit ZUMBACH Electronic at WIRE 2026 for live product demonstrations of the company’s latest technologies and systems showcasing real-time, non-contact measurement for wire and cable applications. They will also get expert consultations on process optimization – meeting with ZUMBACH’s technical specialists to discuss specific production challenges and discover how the company’s solutions can help reduce waste, improve consistency, and boost throughput.

Visitors will gain insight into Industry 4.0 integration and data connectivity and see how ZUMBACH systems integrate with smart factory environments for next-generation manufacturing, and understand the long-term value that ZUMBACH can offer to their operations with decades of global expertise and a strong local presence, combining world-class innovation with personalized service and support. Join us in Düsseldorf at Hall 11, Booth D41, to experience how the cutting-edge technologies are shaping the future of production quality and process optimization across a wide range of wire and cable applications.