The energy industry is central to an ongoing transformation, especially in the field of renewable energy, where wind power is rapidly expanding with turbines being installed in diverse and challenging environments. Behind the scenes, lies a network of highly specialized components, working together to ensure that these systems operate with reliability, precision, and safety. One of the essential components are—medium voltage rubber cables, as they ensure safe and efficient operations, guaranteeing a balance of electrical insulation, mechanical strength, environmental resistance, flexibility and vibration damping.

Alongside manufacturers who must deliver products with specific technical and performance requirements, Mixer S.p.A. brings nearly three decades of focused expertise in the cable industry, developing rubber-based compounds including for medium voltage applications. This deep specialization allows the Italian company to supply materials that directly contribute to the reliability, efficiency, and technical performance of power cables.

Watch: Top Cable Companies in India

EKOPREN® is the comprehensive offer provided by Mixer S.p.A., including a full range of grades dedicated to medium voltage insulation up to 69 kV. As part of a broader portfolio, this family of products represents a strategic pillar for the company, the result of continuous technological refinement and an ability to translate industry needs into tailored solutions. The compounds are designed to meet technical specifications, also supporting the demanding performance required in various applications such as wind generation, where materials must endure challenging environments and ensure the seamless operation of critical infrastructure.

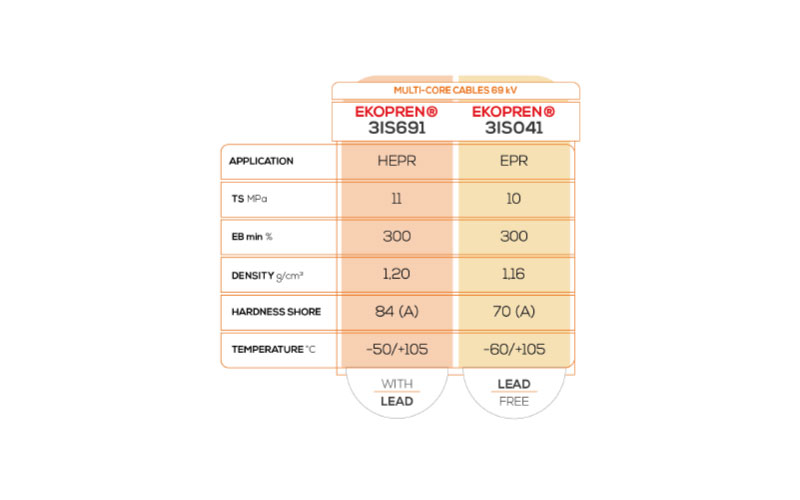

Merging high performance and attention to environmental aspects, Mixer S.p.A. developed in its portfolio both leaded and lead-free compounds suitable as insulation materials up to 69 kV and specific for wind turbines applications. The grades, namely EKOPREN® 3IS691 and EKOPREN® 3IS041, have been finely tuned to withstand bending and twisting movements that occur in moving parts of the wind turbines like the rotor hub or the nacelle. As a matter of fact, since both grades are EPR based, they can withstand repeated torsional stress and absorb mechanical shocks, reducing wear and tear. Equally important, they completely comply with the international specifications, such as IEC or VDE standards, for operating temperatures from -50°C/-60°C to 90°C and 105°C, ensuring reliable power transmission and control even in offshore and high-altitude installations. Alongside this, such grades can be used for both single and multicore cables due to their low deformation in processes that involve a second step of peroxide-induced crosslinking for the sheathing extrusion.

Also Read: NAVANK: Focusing on Category Leadership with Performance-Critical Niches in Compounds

In an ever-evolving industry, Mixer S.p.A. continues to strengthen its innovative vision. The ongoing expansion of the EKOPREN® product line reflects this proactive approach to delivering tailored solutions and supporting customers in meeting both today’s and tomorrow’s challenges.