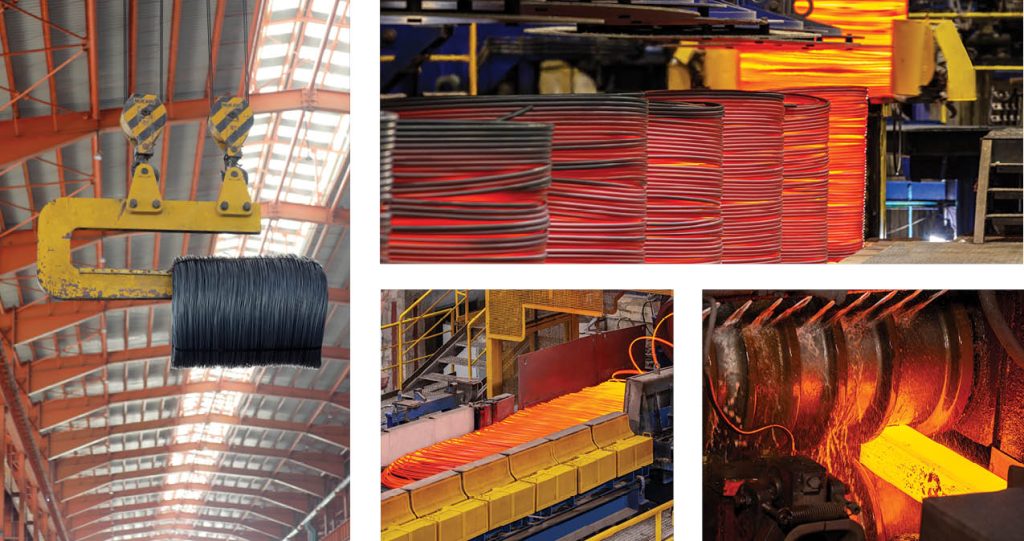

Mukand Limited, a Bajaj Group company, having a rich experience of manufacturing alloy steel, stainless steel, and heavy machinery, is actively expanding its market presence both domestically and internationally through strategic investments in process automation and digital transformation. In an exclusive interview with Wire & Cable India, Mr. Neeraj Kant, CEO of Mukand Limited, shares insights into how the company is formulating strategies to ensure a steady supply of raw materials, manage price volatility, and sustain market stability—all while maintaining a competitive edge in the steel wire sector.

Wire & Cable India: What are the current trends shaping the wire and cable industry in India, especially in the context of the steel wire sector?

Neeraj Kant: The wire and cable industry in India is undergoing a dynamic transformation, driven by rapid infrastructure development, advancements in manufacturing, and growing demands across multiple sectors. In the stainless steel wire segment, the key trends shaping the industry include the rise in infrastructure and power projects, the growth of the automotive and EV sector, and the rising demand for high-tensile and specialty wires.

India’s emphasis on infrastructure development—including highways, metro rail networks, and smart cities—is fueling the demand for high-quality stainless steel wires in construction and power transmission applications. Additionally, the growth of solar and wind power generation projects, where stainless steel wires play a crucial role, is creating new market opportunities. Government initiatives such as ‘Make in India’ and ‘Atmanirbhar Bharat’ are further accelerating domestic manufacturing growth.

With the expansion of the electric vehicle (EV) industry, there is an increased need for high-performance stainless steel products in the automotive sector including automotive components, suspension systems, and fasteners. Lightweight, high-strength stainless steel wire solutions are becoming essential to improve fuel efficiency and enhance vehicle performance.

Furthermore, industries such as oil & gas, renewable energy, construction, and general engineering require superior-grade steel wires with high tensile strength, corrosion resistance, and durability. Mukand Limited is actively innovating in this space to meet the evolving demands of these industries.

Watch: Top Cable Companies in India

WCI: How do you see the Budget for FY2025-26 impacting the steel wire industry, and what opportunities does it offer for the sector?

NK: The Union Budget 2025 presented a promising and forward-looking roadmap for India’s economic growth. The infrastructure development is taking center stage and so is the growth of the steel wire and cable industry. The Finance Minister has outlined a strategic vision to accelerate India’s progress towards ‘Viksit Bharat 2047’, despite global economic challenges.

With India maintaining its status as one of the fastest-growing economies, with GDP growth projected at around 6.5 percent, the budget signals strong government backing for industrial expansion. A key highlight is the substantial allocation for capital expenditure focusing on asset creation, urban infrastructure, and manufacturing growth. This investment will have a direct and positive impact on the stainless steel wire industry, creating multiple opportunities for growth.

In a nutshell, some of the key budgetary measures impacting the Indian stainless steel wire industry are-an infrastructure push driving demand for stainless steel wires, support for domestic manufacturing & MSMEs, steps taken to reduce the cost of raw material for the steel sector, and safeguard duties. However, we need to pay greater attention to factors like availability of domestic stainless steel scrap to reduce reliance on imports and increase the consumption of stainless steel long products in the domestic market.

WCI: How do you see Indian stainless steel wire manufacturers competing with global players to strengthen their position in the global market?

NK: Indian stainless steel wire manufacturers have made significant strides in recent years, positioning themselves competitively on the global stage. Indian manufacturers have aligned their production processes with international quality standards, including ASTM, DIN, and ISO certifications. This alignment ensures that products meet global benchmarks, facilitating acceptance in international markets.

In addition to these, Indian manufacturers are actively engaging in strategic collaborations to enhance their global footprint. Through their unwavering commitment to quality, strategic pricing, and technological advancements, Indian stainless steel wire manufacturers have solidified their position as formidable competitors in the global market. The industry’s future is bright, with sustained growth and innovation expected to drive further success.

WCI: Fluctuation in raw materials’ price has been a serious challenge for the steel industry. How do you plan to overcome the challenges and how is the industry is adapting to these challenges

NK: The volatility in prices of key inputs, like nickel, chromium, and iron ore, is driven by global supply-demand imbalances, geopolitical tensions, and logistical disruptions, which have impacted the production costs and pricing strategies for the stainless steel industry in general. In order to overcome these challenges, we are focusing on a multi-pronged approach.

First, we are enhancing our supply chain agility by diversifying our raw material sourcing. This includes building stronger relationships with multiple suppliers across regions to mitigate risks of sudden price surge or supply disruptions, such as recent nickel shortages due to Indonesian export constraints or shipping delays caused by the Red Sea crisis.

Second, we are investing in operational efficiency by optimizing our production processes to reduce waste and improve yield. This allows us to absorb some of the cost pressures more effectively, without impacting the customers.

Third, we’re exploring long-term contracts and hedging strategies to lock-in prices for critical raw materials and provide cost predictability, thus ensuring stability for our company and our clients.

Now, looking at the broader industry, we believe that adaptation will hinge on collaboration and innovation. We’re seeing a shift toward greater use of recycled stainless steel, which not only reduces dependency on volatile raw material markets but also aligns with global decarbonization goals, an area where Mukand Limited is actively contributing through its sustainable practices.

The industry is also likely to adopt more advanced forecasting tools and data analytics to anticipate price trends and adjust strategies.

To sum it up, while raw material price fluctuations pose a challenge to the industry, it also pushes the industry to evolve. At Mukand Limited, we’re committed to staying ahead by blending our strategic foresight with operational excellence, ensuring that we deliver value to our customers even in a turbulent market.

Some key trends shaping the stainless steel wire industry include rise in infrastructure and power projects, growth in the automotive and EV sector, and the rising demand for high-tensile and specialty wires.

WCI: What are the recent innovations and sustainability initiatives adopted by your company?

NK: At Mukand Limited, we continuously strive for excellence, in terms of quality, innovation, and sustainability, to maintain our position as a leader in the stainless steel wire industry. Our recent developments span technological advancements, process improvements and sustainability initiatives, all aimed at meeting the evolving demands of domestic and global markets.

One of our recent key milestones is our focus on sustainability and renewable energy integration. We partnered with Tata Power Renewable Energy Limited to establish a 43.75 MW captive solar project in Jamkhed, Maharashtra that is expected to generate nearly 100 million units of clean energy annually and is expected to offset 54,687 tonne CO2 emissions per year. This initiative underscores our dedication to reducing carbon footprint while ensuring a stable power supply for our operations. It is also a significant step toward aligning with India’s green energy goals and enhancing our operational efficiency.

Additionally, in our industrial machinery division, we continue to deliver specialized solutions, such as heavy-duty EOT cranes and bulk material handling equipment. A recent highlight is completion and delivery of one of the largest cranes in India with an unprecedented 91-meter span, pioneering a new achievement in India’s heavy machinery landscape. In addition to that, we successfully manufactured our first-ever coke bucket and carriage, a critical component in the coke dry quenching system.

WCI: How does your company’s alloy and stainless steel solutions meet the unique demands of different industries?

NK: With a legacy spanning decades, Mukand Limited has been a trusted leader in delivering high-quality alloy and stainless steel products to a wide array of industries. Our commitment to innovation, precision, and excellence has positioned us at the forefront of the steel industry, meeting the evolving demands of modern engineering and manufacturing.

The company’s alloy steel plays a pivotal role in the automobile and auto component industry, serving as the foundation for critical components that drive performance and safety. Renowned for its exceptional strength, durability, and reliability, our alloy steel is a preferred choice for manufacturing fasteners & bearings, ensuring structural integrity and long-term reliability. It is also essential for crankshafts and steering components, delivering superior performance in high-stress environments. Additionally, our alloy steel enhances vehicle safety and ride comfort with suspension springs and braking systems. Lastly, it plays a crucial role in fuel injection equipment and drive axles, supporting advanced automotive engineering, including common rail diesel injection systems.

In the stainless steel industry, we supply high-performance materials that are fundamental to multiple sectors. Our stainless steel has superior corrosion resistance, high-temperature tolerance, and exceptional mechanical properties which makes it a critical component in the oil & gas industry, power & nuclear sectors, automotive industry, and chemical & pump industry.

In the oil and gas industry, our corrosion-resistant stainless steel protects vital infrastructure, ensuring longevity and operational safety. In the power and nuclear sectors, it supports high-pressure and high-temperature applications, enabling efficient and secure energy generation. Further, in the automotive industry, precision-engineered stainless steel components enhance vehicle performance, longevity, and fuel efficiency. Lastly, in the chemical and pump industry, our stainless steel’s resistance to extreme temperatures and aggressive chemical environments makes it the ideal choice for fluid handling systems.

Beyond alloy and stainless steel, Mukand Limited is also a recognized leader in the design and manufacturing of heavy-duty cranes, catering to steel plants, shipyards, ports, and infrastructure projects.The company’s heavy-duty cranes are trusted across industries for their robust performance, durability, and cutting-edge technology, further reinforcing its position in the industrial solutions.

Also Read: Systematic Group Targets New-Age Markets With Specialized Wires

WCI: Can you tell us about your global presence and key export markets for stainless steel products?

NK: We’ve strengthened our global presence by expanding our export markets. Our stainless steel products now reach over 20 countries, including the UAE, Germany, Italy, Australia, Japan, and emerging markets like Vietnam, driven by consistent quality and innovation. This growth is supported by our ISO 9001:2015 and IATF 16949 certifications, which affirm our adherence to international standards.

WCI: What are your future growth plans aimed at strengthening your market position in the steel wire segment?

NK: Looking ahead, Mukand Limited aims to further expand its market presence, both domestically and internationally, by investing in process automation, and digital transformation. Our growth strategy focuses on enhancing production efficiency, meeting evolving customer demands, and expanding our global footprint.

Our R&D team is working with some of the leading metallurgical institutes and universities to bring-in innovations in steel wire manufacturing, with a sharp focus on developing new alloy compositions that offer higher strength, corrosion resistance, and temperature tolerance.

Mukand Limited is also working on reducing its carbon footprint significantly by 2030 through energy-efficient production methods and renewable energy adoption and advanced metal recovery processes that will minimize raw material wastage and promote circular economy practices.

Our vision is to be at the forefront of the specialty steel and engineering industry, delivering unmatched quality, sustainability, and technological excellence while continuing to contribute to India’s growth in the manufacturing sector and global industrial landscape.

Our R&D team is working with some of the leading metallurgical institutes and universities to bring-in innovations in steel wire manufacturing, focusing on developing new alloy compositions that offer higher strength, corrosion resistance, and temperature tolerance.