In an exclusive interaction with Wire & Cable India, Mr. Yashovardhan Chordia, CEO and Deputy Managing Director of Rajratan Global Wire Limited, shares insights into the company’s robust expansion strategy. He highlights the commissioning of a manufacturing facility in Chennai with a scalable capacity of 60,000 TPA, aims to solidify company’s position as a world-class, preferred supplier of bead wire to the global tyre industry, and the introduction of 10,000 TPA wire rope production in the Pithampur facility. With a focus on digitalization, sustainability, and product diversification, Rajratan is strengthening its position as a global leader in the steel wire sector, aiming to triple its exports by FY26.

Wire & Cable India: Rajratan has set up a greenfield manufacturing facility in Chennai. What is your vision behind establishing this new facility and how will it impact overall business performance?

Yashovardhan Chordia: The Chennai facility is a cornerstone of Rajratan’s strategy to expand its global footprint, enhance competitiveness through scale and efficiency, and solidify its position as a world-class, preferred supplier of bead wire to the global tyre industry, all while adhering to high standards of quality and sustainability. Additionally, since a large number of major tyre manufacturers are located in the southern part of India, the Chennai plant will play a crucial role in serving these customers more efficiently and responsively. This strategic location not only strengthens our supply chain but also helps us build closer partnerships with key clients, ultimately contributing to improved business performance and customer satisfaction.

WCI: How will this facility enhance the overall capacity of Rajratan?

YC: The new manufacturing facility in Chennai significantly enhances Rajratan’s overall production capacity, marking a strategic leap towards becoming a global entity.

Initially, the Chennai facility, which was commissioned during the financial year 2023-24 and began commercial production in August 2024, added 30,000 TPA to Rajratan’s manufacturing capacity. Now, the Chennai facility has been designed with infrastructure to support a scalable monthly capacity of 5,000 tons (equivalent to 60,000 TPA) which can be further scaled.

Watch: Top Cable Companies in India

WCI: The company has introduced wire rope at its Pithampur plant. What is the production capacity of this new segment? How does this horizontal expansion impact your overall steel wire business?

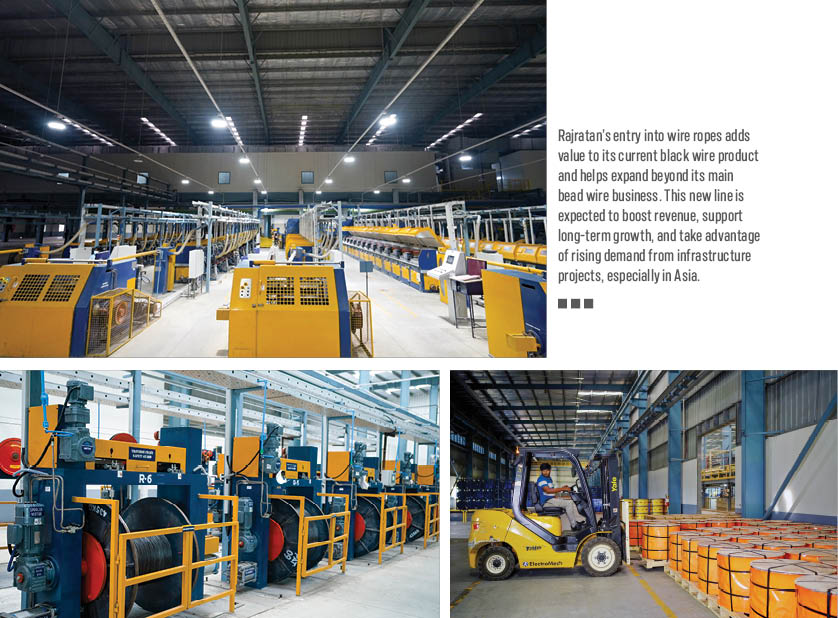

YC: Rajratan has introduced wire rope manufacturing at its Pithampur plant, which represents a forward integration from its existing production of high-carbon steel wire (also known as black wire). The company intends to manufacture 10,000 TPA of wire ropes at its Pithampur facility.

Rajratan’s entry into wire ropes adds value to its current black wire product and helps expand beyond its main bead wire business. This new line is expected to boost revenue, support long-term growth, and take advantage of rising demand from infrastructure projects, especially in Asia. It also offers good export opportunities, supporting the company’s global plans.

WCI: Shed light on your manufacturing facilities and their production capacities?

YC: In India, we have two manufacturing facilities. One in Pithampur, Madhya Pradesh with a production capacity of 72,000 TPA. Another one in Chennai, Tamil Nadu, with a manufacturing capacity of 60,000 TPA, which can be further scaled, whose initial commissioned manufacturing capacity for bead wire was 30,000 TPA. And in Ratchaburi, Thailand we have a 60,000 TPA manufacturing facility.

WCI: Rajratan aims to triple exports in FY26. Which product segments will drive this growth, and what strategies are you implementing to achieve this goal? Which markets are you eyeing for enhanced exports?

YC: Rajratan’s strategy revolves around leveraging its expanded, high-quality, and cost-efficient manufacturing capacity from the new Chennai plant, coupled with focused international sales and marketing efforts and product diversification, to significantly grow its global footprint and reduce dependence on any single market or region.

The growth in exports will be primarily driven by two key product segments, tyre bead wire and high carbon steel wire. We already have a significant presence in the Southeast Asian market, and we are now strategically aiming to expand further into Europe and the United States. This approach builds on our strong relationships with leading global tyre companies, giving us a solid base to grow in new markets.

WCI: How do you see Indian steel wire manufacturers competing with global players in terms of quality, pricing, and technological advancements?

YC: Indian steel manufacturers are striving to compete globally by leveraging domestic raw materials and labour for cost advantages. However, they face significant challenges from high capital costs, logistics issues, and non-creditable taxes, which directly impact pricing competitiveness and make them vulnerable to cheaper imports. In terms of quality and technology, there is a strong push towards the adoption of advanced digital tools and modernization initiatives aimed at improving efficiency, streamlining production processes, and aligning with global standards, ultimately enhancing product quality and strengthening overall competitiveness.

The Indian steel industry is growing rapidly, driven by strong demand from construction, railways, and the auto sector. This growth is supported by government initiatives like the National Steel Policy and the PLI scheme, which aim to boost production and reduce imports.

WCI: What are the key trends and challenges shaping the Indian steel wire industry, and how is the sector evolving to address them?

YC: The Indian steel wire industry is currently undergoing significant transformation, fueled by strong demand from core sectors like construction, railways, and automotive. Government initiatives such as the National Steel Policy and the Production-Linked Incentive (PLI) scheme are playing a pivotal role in boosting domestic production, encouraging investment, and reducing reliance on imports. Companies are increasingly adopting digital technologies like AI, IoT, robotics, and automation to enhance efficiency, improve product quality, and stay globally competitive.

However, the industry faces notable challenges, including high production and transportation costs, expensive financing, heavy taxation, and stiff competition from cheaper imports. Additionally, outdated technologies and inconsistent demand from key sectors like real estate and automotive continue to pose hurdles. To overcome these issues, the sector is embracing sustainability through energy-efficient processes and reducing logistics costs. Consolidation through mergers, partnerships, and workforce upskilling are also key strategies being pursued to strengthen the industry’s global standing and long-term resilience.

WCI: The company has recently achieved the TPM excellence award for its Pithampur facility. How do you plan to build on this momentum moving forward for your Chennai and Thailand facilities?

YC: Rajratan Limited, after earning the TPM Excellence Award Category A for its Pithampur plant, is now replicating these world-class standards at its Chennai and Thailand facilities. The Chennai plant, operational since August 2024, integrates TPM from the outset, supported by advanced infrastructure, digital systems, and automation. TPM implementation at both the Chennai and Thailand facilities is currently in progress, guided by the valuable learnings and best practices from the Pithampur plant. In Thailand, Rajratan has already made significant progress and is actively working towards TPM certification.

Also Read: Real Ispat & Power: Driving Innovation and Sustainability in Steel Wire Manufacturing

WCI: What are your future growth plans aimed at strengthening your market position in the steel wire segment?

YC: Rajratan plans to strengthen its market position by expanding into wire rope manufacturing with a 10,000 TPA facility at Pithampur. It is investing in R&D and technical talent to tap into strong demand from sectors like construction, mining, and transport. The company is also developing high tensile wires for infrastructure, and focusing on sustainable bead wire using recycled materials and EV tyre applications. These steps aim to diversify its offerings and build long-term business resilience.

The company is focusing on sustainable bead wire using recycled materials and EV tyre applications.