SETIC & POURTIER will participate in Wire Düsseldorf and will showcase the latest innovations, such as a 1250 mm single twist assembly line and HVDC prespiralling and compacting head.

Feb 05, 2026

SETIC & POURTIER will be participating in the Wire Düsseldorf 2026 trade fair. This edition marks a major milestone with the presentation of a unified brand identity under the signature: ‘Wire and cable solutions powering a changing world’, converging industrial expertise and supporting customers through profound digital and energy transformations.

Acting as a global strategic partner for stranding/cabling solutions, SETIC & POURTIER’s product portfolio gives the wire & cable industry the ability to select different state-of-the-art and advanced twinning and cabling solutions for producing a wide range of cables. Each solution is perfectly adapted to each of our partners.

At the booth, SETIC & POURTIER will showcase key technologies illustrating the versatility and performance of their cabling solutions:

Watch: Top Cable Companies in India

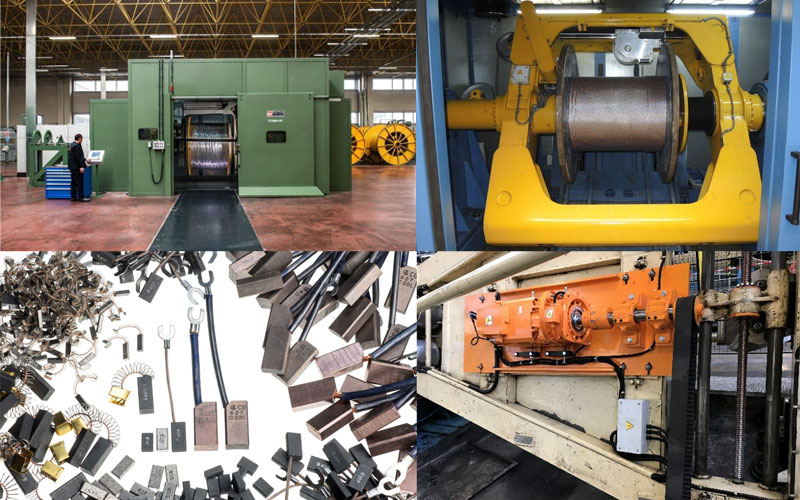

The booth will feature a 1250 mm single twist assembly line, together with single backtwist pay-offs. This configuration, dedicated to control, instrumentation, and data cables, offers high flexibility for sensitive products and dynamic applications, including EV charging and battery cables.

The company will also showcase HVDC prespiralling and compacting head. It is an impressive unit designed for HVDC power cable applications. This unit ensures a high compaction rate, excellent roundness of the final conductor, and accurate roller settings, supporting the most demanding power transmission requirements.

The enhanced high-speed double twist bunchers, single twist take-up with backtwist payoffs and various complete strander solutions are perfectly adapted for the production of EV charging, batteries and data cables for this industry.

SETIC & POURTIER also fulfils the needs for industrial data cables, Industrial Internet of Things (IIoT), robot and strong growth in the global LAN market with its one-step or two-step solutions, such as double twist twinners & quadders, group twinners.

Thierry Pietroniro, Area Director, commented: “Our wide range of compacted 61 wires copper/aluminium large double twist machines (up to 1250 MCM / 630 mm² and reel diameters up to 2600 mm) offers decisive advantages-Over 40% increase in productivity, and less than 30% reduction in energy consumption compared with traditional methods, these machines can manufacture multiple LV/MV cable sections from a single input wire dimension, making them perfect to boost productivity and reduce operating costs.’’

SETIC & POURTIER also connects its customers to all energy sources. The demand for clean energy, including improved infrastructure, has been on the rise in the past few years, resulting in new market challenges. SETIC & POURTIER has the most advanced solutions to meet these challenges for sustainable clean energy and infrastructure, proposing heavy-duty stranders, cablers, screening, planetary and armouring lines. Its high-efficiency revolutionary multiwire concentric stranding line is also widely used to boost the productivity for low and medium energy cables.

The company continues to expand its wide range of offerings with a higher number of wires up to 169 for rigid stranders together with pulling capstan up to 80 tons, and XL drum twisters up to 60 tons. All of these machines are designed and manufactured with the highest standards in design and manufacturing to produce all types of high-voltage and extra-high-voltage power cables, from overhead cable (including ACCC™, ACSS-TW and ACSR-TW) to submarine or land cables AC type (using high quality Milliken conductor) or DC type (using large round compacted conductor or profiled “Keystone” wires).

Aware of its social and environmental responsibilities, SETIC & POURTIER places decarbonization at the heart of its strategy.

Also Read: STL Collaborates With Colt Technology Services to Conduct Multi-core Fibre Trial

The C2S Customer Services department is the ideal partner to combine productivity with sustainability. By providing specialized spare parts, upgrades and maintenance, C2S extends the lifetime of existing machines, minimizing environmental impact while optimizing production line performance.

Meanwhile, BOW TECHNOLOGY continues to innovate with its high-grade carbon bows for all brands of double twist equipment. The patented GreenBow2 closed-bow model ensures significant energy savings of up to 30%, actively contributing to a more sustainable industry.

Customers can meet the experts at Hall 10, Booth F59, to discover how the company’s solutions enable digital and energy transformations worldwide.