Metalube, UK-based manufacturer of specialist industrial lubricants, is constantly delivering innovation and continuing to push the capabilities of lubricant performance and efficiency across industries. In a recent interaction with Wire & Cable India, they talked about their upcoming next-generation copper wire drawing lubricant- Lubricool 955 which is set for launch in summer 2025; and their foray into the marine and sea cable industries with their in-development SCG cable greases.

Established in 1988, Metalube is a renowned industrial lubricants provider with over 37 years of experience in the manufacture of specialist industrial lubricants. Headquartered in Irlam, Manchester, Metalube is a proud manufacturer and exporter of British products with 95% of their production going out globally across a number of markets and industries.

As a global business, Metalube has operations in India, the Middle East, South America, China and Southeast Asia. Metalube operates a fully integrated manufacturing facility, including a state-of-the-art, on-site laboratory.

Researching lubricant performance and developing innovations are vital aspects of what separates Metalube’s output in the industry. Metalube is constantly investing in their technology centre, ensuring technical excellence and innovation across their existing and future products and services.

Watch: Top Cable Companies in India

Product Offerings

At its inception, Metalube was built around the production of wire and tube drawing lubricants for non-ferrous applications. This led to the development of the leading Lubricool™, Alumol™, and Tubol™ ranges, all renowned products still remaining leaders in the non-ferrous drawing industry and key parts of our product range.

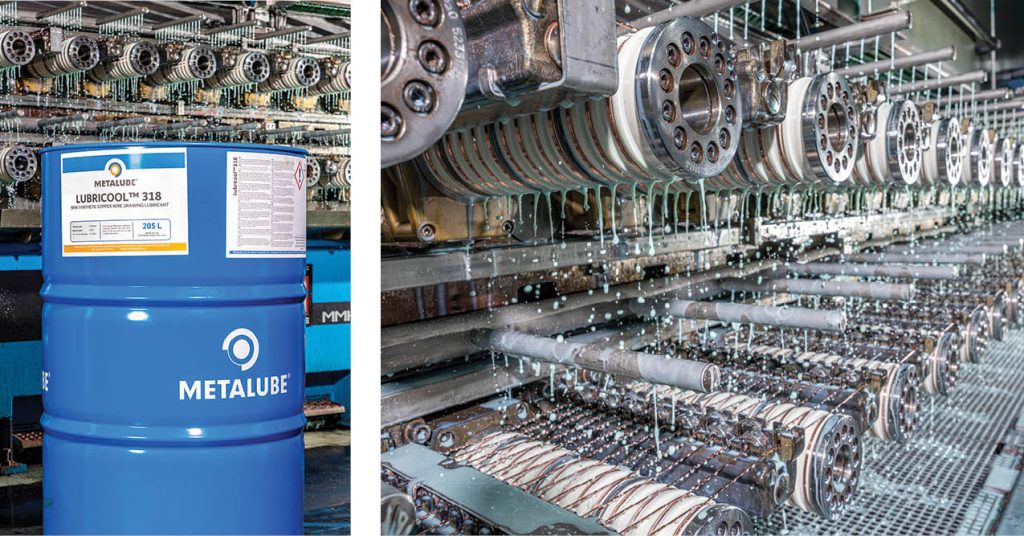

Lubricool™ is our industry-renowned range of water-soluble copper wire drawing lubricants developed to deliver high-performance lubrication to copper wire manufacturers. Supplying wire drawing lubricants to customers across the world, our Lubricool™ range is formulated with the latest in synthetic technologies, having been developed with over 30 years of expertise to work from rod to superfine wire.

Metalube’s Alumol™ range offers the pinnacle of lubrication technology tailored for the intricate process of drawing aluminium and aluminium alloy wire. Crafted through a meticulously balanced blend of natural and synthetic additives, Alumol™ enhances the efficiency of wire drawing machines and significantly elevates their operational performance. At the heart of Alumol™ lies its unparalleled affinity with aluminium, ensuring a robust protective film that delivers outstanding surface quality and prolongs die lifespan.

Metalube’s leading solution for the copper tube drawing industry, Tubol™ is a comprehensive range of lubricants specifically designed for use in drawing non-ferrous tubes used for ACR, sanitary and engineering applications. The ultimate solution for high-performance copper tube drawing lubricants, our product is proudly manufactured in the UK and served worldwide. The Tubol™ range offers the most cutting-edge synthetic and semi-synthetic lubrication technology. Meticulously formulated to surpass the rigorous demands of the industry and fulfil specific customer needs.

Also Read: Traxit Wire Lubrication: Global Expertise and Innovative Strength

Commitment to Innovation

Metalube’s commitment to innovation and high-quality production has been recognised globally with Metalube being awarded the esteemed King’s Award three times! Twice for our contribution to international trade and once for our continued product innovation.

This commitment to offering the best possible products, with exceptional formulations and performance has led to lubricants that are unmatched in the industry. It’s by offering game-changing results to our customers that Metalube is able to continue producing as an industry leader. Delivering innovation and continuing to push the capabilities of lubricant performance and efficiency across industries.

Case Study: 300% Efficiency Increase at a Leading Indian Enamelled Wire Manufacturer after Utilising Alumol 32

These products have allowed Metalube to offer exceptional results for our customers, such as a 300% efficiency increase at a leading Indian enamelled wire manufacturer after utilising Alumol 32 in 2024.

Metalube achieved incredible results by offering extended lubricant life- Alumol 32 extended sump life from a maximum of 6 months to 18 months. This reduced machine downtime and significantly lowered labour costs associated with frequent tank cleaning and lubricant replacement.

The drawn wires were much cleaner, with less lubricant carryover, which simplified the wire cleaning process before enamelling. This resulted in improved wire quality with fewer wire breakages, further enhancing production efficiency.

The longer lifespan of Alumol 32 indirectly reduced costs related to labour, machine downtime, and the purchase of lubricants. By operating continuously for 18 months without requiring a tank change, the customer achieved substantial savings.

For 18 months, the machine processed 1,260 tonnes of aluminium wire, highlighting the robustness and effectiveness of Alumol 32 in supporting continuous, high-volume production.

Lubricool 318 Exceeded the Demands of Niehoff MMH 32 Multi-wire Machine at India’s Leading Wire and Cable Manufacturer

Similar results were observed in 2023, where Lubricool 318 met and exceeded the demands of Niehoff MMH 32

multi-wire machine at one of India’s largest wire and cable manufacturers. By adopting Lubricool 318, the manufacturer achieved production speeds of 31 m/sec for 0.2mm copper wire and an average monthly production of 350 tonnes. Lubricool 318 provided 4.5 year sump life in 7,500 litre system and is still producing to this day. Excellent pH and emulsion stability and low maintenance are add on benefits.

Next-generation Copper Wire Drawing Lubricant: Lubricool 955

With the development of our next-generation copper wire drawing lubricant, Lubricool 955, we continue to innovate within our field. As demands for higher production output and efficiency increase for wire manufacturers, the demand for lubricant performance also increases.

Lubricool 955 has been designed from its formulation for the next generation of copper wire drawing with increased sump life, decreased lubricant reactivity and reduced downtime. Lubricool 955 has been specially designed for multiwire machines in excess of sixteen wires in both fine and superfine wire applications.

Set to launch in summer 2025, Metalube are confident Lubricool 955 will be a true revolution for the wire drawing industry- Never settling for the bar we set and continuing to seek the next goal for product performance!

Going Beyond Limits: Submarine Cable Grease

We also push our innovation into new industries and fields, such as our new developments into the submarine cable industry, with our in-development SCG cable greases that are set to take our innovative approach to lubrication and grease into the marine and sea cable industries. SCG is a fully synthetic blocking compound designed to maximise the protection of submarine powered cables- utilising a unique blend of synthetic polymers, rheology control additives and fillers to deliver a high-performance, highly adhesive, semi-conductive compound. This powerful compound blend allows SCG to effectively fill interstices between wires and prevent the potential ingress of water.

Sustainability Matters

Metalube has continued to push this growth and momentum while also remaining conscious of our environmental impact and investing into sustainable practices across our business model.

As a company, Metalube understands that in a more socially conscious and environmentally aware landscape, people expect more from their suppliers, asking them to uphold greener standards and more eco-friendly practices within their manufacturing.

Investing heavily into green energy, Metalube has adopted a fleet of electric forklifts, solar panel roofing across our manufacturing site, energy-efficient heating ovens and recycled IBCs/Securing materials.

Metalube’s sustainable practices also extend to our products as we adopt alternative base oils, biodegradable and sustainable complex esters within our product ranges.

This has ensured Metalube to achieve a gold rating from sustainable standards administrator EcoVadis, being in the top 5% of companies in the UK for sustainable practices.

Recognised by several key industry figures, Metalube’s Managing Director, Robert Brown, has been invited to discuss our sustainable practices at panels such as the ‘Energy Innovates’ Conference, reaffirming our company goal of achieving Net-Zero-Emissions by 2050.

Vision

As we continue to advocate for a change in the industry, we hope to take everything we have learnt and adopted and pass it onto the industry at large. Our goal is to push the industry towards a better, more sustainable manufacturing.

Metalube has continued to show that our long and acclaimed history is just the start of our ambitions. As we continue to expand into new markets and new industries, Metalube’s aim to offer a truly next-generation range of industry solutions continues to grow year on year.

Our success also lies in our ability to be flexible, offering unrivalled technical and after-sales support. It is our priority for customers to run at peak efficiency – and for 30 years, Metalube has delivered world-class service and superior-performance products.