Introduction

Wires and Cables are present in our everyday life. Energy and data are transmitted by cables. Preventive fire protection of cables is a topic ever increasing importance since more than forty years now. Flame retardants prevent polymers used for electrical insulation of conductors and mechanical protection of cable constructions from ignition and flame spread.

Different technologies exist to produce flame retardant cable compounds. The best choice for a certain case depends on many factors, mainly on the property profile which the final product must offer, as well as on the applicable base polymers, the added flame retardants, and the available compounding and extrusion technology. Selected possibilities to produce flame retardant cable compounds shall be presented.

Mineral Flame Retardants

Over the years, metal hydrates, especially aluminium hydroxide (ATH, Al(OH)3) and magnesium hydroxide (MDH, Mg(OH)2) have established as the most important flame retardants for the wire and cable industry.

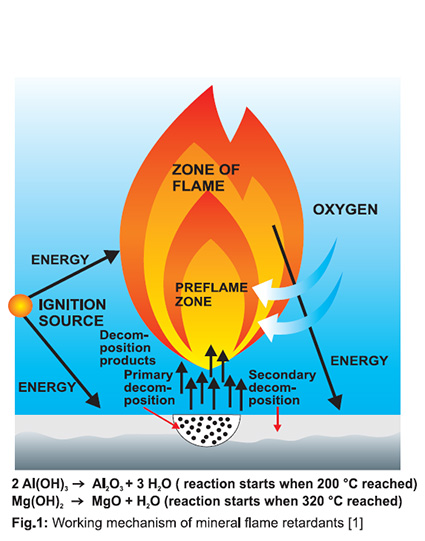

Metal hydrates release water at elevated temperatures in an endothermic reaction which delays the decomposition of the polymer. Released water cools the material surface and dilutes burnable gases. The residue of the decomposition reaction – alumina – protects the underlying polymer from heat and adsorbs decomposition products of the polymer, as well as soot particles to reduce the smoke density.

A schematic drawing of the working mechanism of mineral flame retardants is shown in below Figure.

The applicability of a certain mineral flame retardant depends on the compounding and extrusion temperatures. If, for example, ATH shall be used the mass temperature during the processing of the compound should not exceed 190 °C and respectively 300°C for compounds with MDH, to prevent the decomposition of the flame retardant.

Types of Cable compounds

PVC Cable Compounds

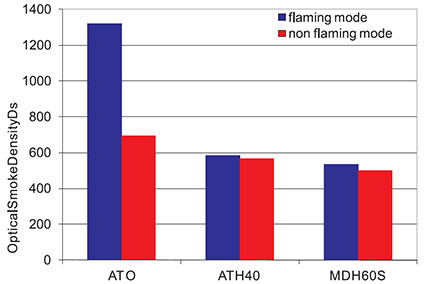

Cable compounds made from PVC often contain ATO (antimony trioxide) as flame retardant synergist to the chlorine in the PVC chain. But, due to the working mechanism of ATO and chlorine, large amounts of smoke are formed when an ATO-containing PVC compound starts to burn, as demonstrated in Figure 2.

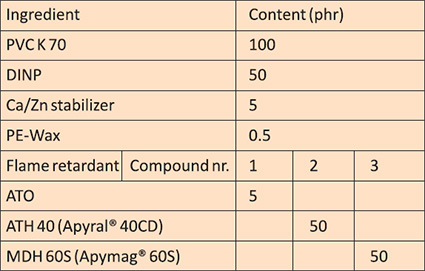

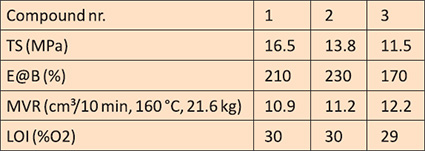

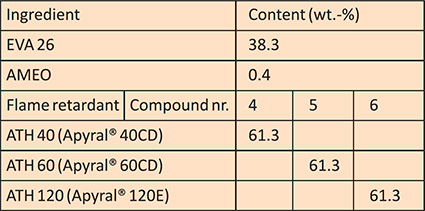

To reduce the smoke formation, flame retardants like ATH and MDH can be used in addition to or instead of ATO. A typical PVC cable compound formulation is shown in Table 1. Some data of such compounds which contain ATO, ATH, or MDH as flame retardants are presented in Table 2.

Table 1: PVC cable compound

Table 2: Properties of PVC compounds with different flame retardants

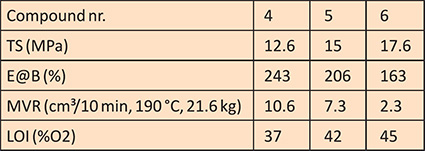

The higher loading level which is required if metal hydrates are used as flame retardants instead of ATO does affect the mechanical properties TS and E@B of the compounds, as shown in Table 2.

One major advantage of metal hydrates as flame retardants over ATO becomes obvious in Figure 2: The smoke development of such PVC compounds in ASTM E 662 smoke chamber tests is compared in the flaming and in the non flaming mode. ATH and MDH reduce the smoke density of burning PVC compounds considerably and can be used for the production of not only flame retardant, but also for low smoke flame retardant (LSFR) PVC compounds.

Fig. 2: Smoke Density of flame retardant PVC compounds

HFFR Cable Compounds

Another class of cable compounds is halogen free flame retardant (HFFR) compounds. As the working mechanism of ATH is based on physical effects, usually high loading levels of this flame retardant are necessary to comply also with strictest flame retardancy standards. Typical loading levels of ATH in HFFR compounds range from 50-70 wt.-%, depending on the requirements for the final product [2].

Thermoplastic polyethylene (PE) or ethylene vinyl acetate (EVA) based compounds with more than 60 wt.-% ATH can be used for the production of HFFR compounds. Other technologies are based on elastomers and thermoplastic elastomers, which may also contain metal hydrates.

One example for an HFFR compound, a thermoplastic EVA based formulation, shall be described more in detail. Compounds 4 to 6 which are flame retarded with 61.3 wt.-% of ATH were prepared according to the formulation shown in Table 3 and their properties which are listed in Table 4 are compared. The ATH grades, which were used to produce these compounds differ in their particle size and their specific surface area which have significant effects on the characteristics of the final product [2].

Table 3: EVA 26 cable compounds

Table 4: Properties of EVA 26 compounds

With increasing specific surface area (BET) of the mineral flame retardant the TS and the LOI values of the compounds improve, whereas the E@B and the MVR – an indicator for the extrusion behavior of a compound – are reduced. These trends of the compound properties can be determined in different polymer matrices and they approve that an optimized cable compound can be designed from different polymers and flame retardants, based on the required cable characteristics for a certain application.

For special application fields, even more demanding cable property profiles must be achieved. In these cases special mineral flame retardants with a silane surface treatment are recommended [3]. Other types of polymers like elastomers or thermoplastic elastomers also provide additional design options for cables, like e.g. for railway vehicles, ships or offshore applications [2, 4].

Summary

Two major technologies for the production of safe and functional cable compounds were presented, PVC based materials, and HFFR solutions.

Due to increasing requirements for cable compounds which must not only meet stringent fire safety standards, but also more and more demanding specifications for smoke development and prevention of the formation of toxic gases HFFR cable compounds become increasingly prominent.

One main flame retardant for such applications is ATH, which can be used in PVC as well as in HFFR compounds. Metal hydrates like ATH do not only provide the required flame retardancy for cable compounds, but they offer additional advantages like reduced smoke formation and they do not release any possibly harmful substances when they are activated.

The article is authored by Ibrahim Cam, Dr. Annika Luks, Dr. Reiner Sauerwein, Nabaltec AG

References:

[1] please refer to: http://www.nabaltec.de/index.php?option=com_content&task=view&id=114&Itemid=249

[2] Nabaltec AG (2010), Brochure Metal Hydrates for Cables.

[3] Luks, A. (2013), Mineral flame retardants for cable compounds, in Schriftenreihe Bahntechnik Aktuell (Band 46/2013) Fire Safety 2013 – Fire Safety in Railway Systems, Editor: Schulz, E., Interdisziplinärer Forschungsverbund Bahntechnik e.V., Berlin.

[4] PINFA (2010), Brochure Innovative and Sustainable Flame Retardants in Transportation, PINFA, Brussels. www.pinfa.eu/library/brochures