October 15, 2014

SIKORA offers the high-end devices of the LASER Series 6000 in addition to classic diameter gauges of the LASER Series 2000. With 2,500 measurements per second, all with extremely high single value precision, LASER Series 6000 allows for an optimum line control and provides reliable statistical data. The gauge heads measure the diameter of wires and cables with an impressive precision and repeatability. SIKORA offers 3 gauge head models for product diameters from 0.2 to 78 mm. The LASER Series 6000 measures precisely transparent products as well.

The devices include an integrated LCD display with control panel. This provides the operator with diameter values at one glance, directly at the measuring device. The high measuring rate of the diameter devices also allows the detection of lumps and neckdowns. Directly integrated in the gauge heads is a universal interface module for all connections such as RS 485, RS 232, Profibus-DP or, alternatively industrial field busses such as CANopen, Ethernet/IP, DeviceNet, Profinet IO.

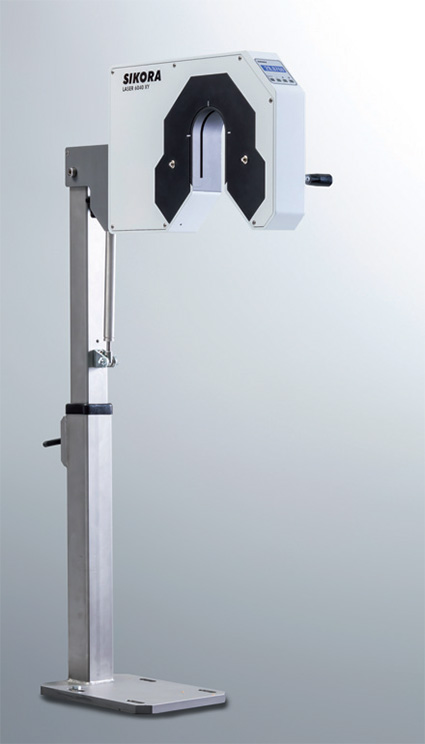

The opening of the gauges is twice as big as the measuring range to ensure an easy and safe passage of the production. A special feature of these devices is the swivel type gauge head. It allows for the gauge head to be easily moved upwards, out of the extrusion line.

The LASER Series 6000 has common interfaces as well as an optional Wi-Fi interface, which allows a direct connection to a smartphone or laptop. The Wi-Fi interface is used for diagnosis and quality control. Measuring values, trend and statistical data, but also video signals are transferred.

SIKORA offers a free app for displaying measuring values, trends, statistics or video signals at smartphones. The operator easily logs in via the Wi-Fi interface, and production data are directly displayed at the smart phone. The app allows also a calibration of the gauge head. According to ISO 9001 with all data listed in a log file, a detailed test certificate in PDF format can be transmitted to the QM department, and is stored for further reference.