October 3, 2013

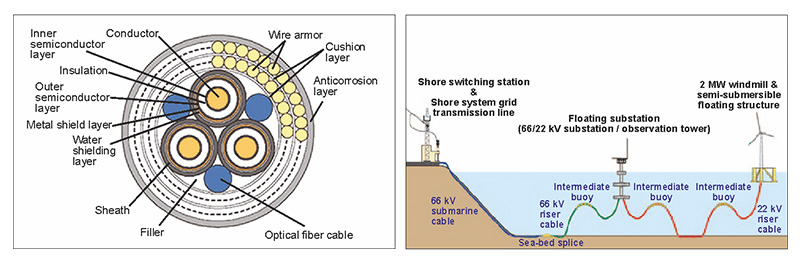

In the “Fukushima Floating Offshore Wind Farm Demonstration project” by Ministry of Economy, Trade and Industry, Furukawa Electric and VISCAS Corporation successfully developed and manufactured the special-high voltage riser cable that electrically connects, under the sea, a 2 MW floating offshore wind turbine equipment (power generation equipment) and an offshore substation (substation equipment); and Shimizu Corporation successfully installed the cables in the actual sea.

The special-high voltage riser cable is a power cable that floats in the sea and dynamically follows the movements of the floating equipment, the wave and the tide. There is no other example of development and manufacturing of this kind of cable and its installation in the actual sea.

In the experimental study, Furukawa Electric is responsible for the overall development of the power transmission system for the floating offshore wind farm and VISCAS Corporation is responsible for the manufacturing and jointing of the special-high voltage riser cable. Shimizu Corporation, as a joint venture with Nippon Steel and Sumikin Engineering Co., Ltd, is responsible for the towing and anchoring of the floating offshore wind turbine equipment from Naraha to a sea area a distance of about 20 km, the laying and the burying of a submarine cable that connects Naraha and the anchoring sea area and the connection of the power generation equipment and the substation equipment with the riser cables.

The special-high voltage riser cables, installed for this time, consist of two kinds of cables. One is a 66 kV cable (0.9 km × one cable), which connects the substation equipment and the submarine cable drawn from Naraha; the other is 2.2 kV cable (2.3 km × one cable), which connects the power generation equipment and the substation equipment. Outside diameter and weight are 146 mm, approx. 42 kg/m for 22 kV cable and 175 mm, approx. 52 kg/m for 66 kV cable. These cables have an excellent water-tight performance that prevents seawater penetration, which used to be considered a weak point, and a fatigue resistance performance even for long-term usage. To both riser cables, buoys are attached at the midpoint from the floating equipment and the bottom of the sea, and installed to draw the S-shape in the sea. The S-shaped part is an adjusting extra length to follow the movements and the ups and downs of the floating equipment. Behaviour analysis technology of Furukawa Electric played an invaluable role.

Meanwhile, the installation of the special-high voltage riser cable in the actual sea area is a construction with a high degree of difficulty because of the influence of waves and tides. Shimizu Corporation overcame the challenges in the construction, that is, the shape in sea water (S-shaped) management, the cable length adjustment to maintain the shape and the cable end and the floating equipment joint work, etc., by taking advantage of its high level of technology for marine construction developed in the construction of the deep-ocean water intake facilities and others.