The increasing demand for cables for applications in automotive, data transfer and other industrial applications as well as the constantly growing requirements for increased transmission speeds, data security and quality parameters are also making greater and greater demands on the effectiveness and the quality of cable screening with regard to the braids and foil taping of cables.

SPIRKA SCHNELLFLECHTER GMBH offers a comprehensive product portfolio of braiding machines, dancer-controlled payoffs and take-ups, longitudinal foil taping attachments, concentric taping as integrated or separate units for the above areas of application and mentioned requirements which are well known to cable manufacturers.

Fault-free braids, precision in lay lengths, sensitive handling of the core material and gentle, jolt-free winding of the cables before and after the braiding process are decisive for the quality of the cables and their competitiveness. The same applies for precision taping processes below and after the braiding, whether longitudinal or concentric taping is used. The lay lengths can be set continuously by the motorised capstans, tensions on the cable are monitored with dancer control and are reproducible, and wire tensions can be set and controlled precisely.

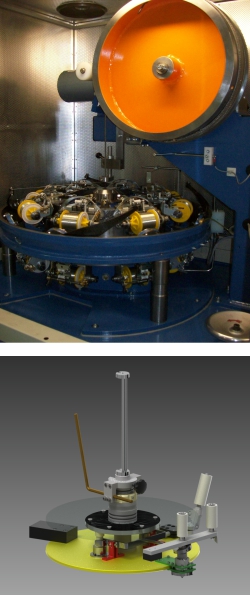

The latest version of a 16 carrier Braider will be presented with following features

The latest version of a 16 carrier Braider will be presented with following features

- New generation of PLC, HMI and drives

- Optional energy and temperature measuring system

- Optional remote control and diagnostic system

- Optional Upgraded Empty Bobbin Detection System

This braider can be provided with integrated and standalone concentric taping units in line featured optimized regulation for precise pre-setting of tape tensions and a harmonized brake system for fine tuning.

SPIRKA SCHNELLFLECHTER GMBH is a very complex provider of braiding, coiling and spooling machines in addition to accessory equipment for almost all braiding and spiralling application areas for customers in the cable and hose industry and for manufacturers of all types of catheters. In the main program, the braiding machine program comprises vertical and horizontal rotation braiding machines with 8 to 36 spools which can be used for a maximum product diameter up to 65 mm.

The spiraling machines with up to 24 spools in the vertical area and up to 36 spools in the horizontal area as well as manual and fully automatic spooling machines round off the program are for the users in the cable and hose industry. An important advantage for all customers worldwide is the possibility of being able to obtain the necessary completion equipment such as band feeders, central band coilers, winding and unwinding technology, empty spool detection systems from one provider regardless of the main equipment.

The long cooperation with WARDWELL BRAIDING CO./USA as member of same group helps to offer the most comprehensive range of braiding and winding machines for nearly all screening applications.