Global competition is getting tougher and fierce, instigates manufacturers to reduce cost and waste, and manage delivery lengths better and more accurate. In the converting, woven, non-woven, paper, film, foil as well as many process industries, speed and length of product is measured by contact encoders. In most cases the product is contacted by a wheel and the wheel rotation is translated into encoder pulses, these pulses are counted by an electronic counter or by a PLC counter. Depending on the circumference of the wheel and the number of pulses generated for each rotation of the wheel/encoder, the applied calibration factor, etc… the length or speed is measured. In all industries this method of length or speed measuring is used since over 100 years.

Mechanical Measurement = Reduced Accuracy

All contact methods of measuring Speed or Length, are associated with problems, such as:

- reduced accuracy

- problems associated with slippage

- material stretch inducing large errors

- wear of the measuring wheel

- contamination of the measuring wheel frequent need for calibration

- encoders wearing out

- Not possible to communicate with the sensor by modern communication interfaces.

As far as managing product length, the manufacturer is faced with problems such as:

- Shipping excess material due to slippage

- Measuring errors due to product characteristics such as stretch, surface irregularities, etc.

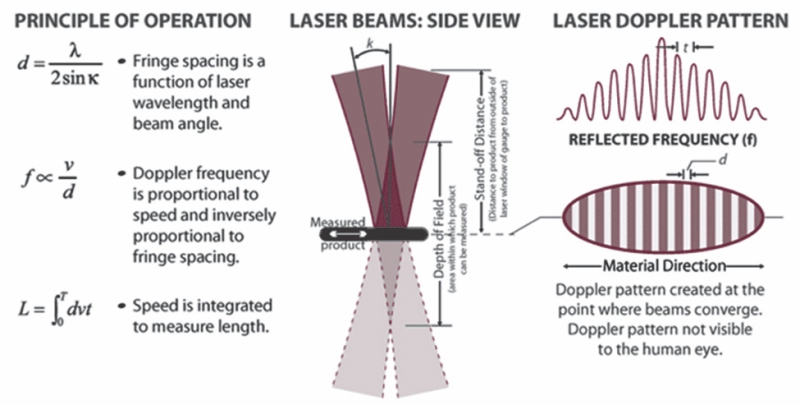

Proton Products InteliSENS® SL and SLR Series of Non-Contact Laser Doppler Velocimetry (LDV) Speed and Length gauges measure products that are made in a continuous process, incl. Wire & Cable. The gauge uses two laser beams to create a laser Doppler fringe on the product surface. Receiving optics collect the reflected Doppler signal which is then processed using advanced high-speed Digital Signal Processing to ensure the measurement data is accurate, reliable and repeatable.

The gauge measures in the toughest production environments. The gauges are extremely easy to install, set up and integrate into an existing control system, or can be used as a stand-alone system. All outputs are integrated within the Sensor.

The inteliSENS® SLmini or SLRmini gauge is typically used to measure the length of wire and cable.

Applications in process industries are countless. Contact encoders result in low accuracy, over-length giveaways due to slippage or unwanted product marking, the inteliSENS® SLmini or SLRmini provides the solution and quick Return on investment.

Applications in process industries are countless. Contact encoders result in low accuracy, over-length giveaways due to slippage or unwanted product marking, the inteliSENS® SLmini or SLRmini provides the solution and quick Return on investment.

The gauge emits two laser beams at a moving object and analyses the reflected light to obtain extremely accurate measurements. At the point where the laser beams cross, a pattern of light bars is projected onto the surface of the measured object. This pattern is not discernable to the human eye because it is so fine. The human eye sees just a red dot or red line.

The gauge relies on defects passing through this Doppler bar pattern to generate a characteristic frequency proportionate with the speed. This frequency is detected by the Avalanche Diode inside the gauge head, and the Digital Signal Processor calculates the speed of the moving product.

Typical Applications in the process industries:

| Speed synchronisation | Cut-to- Length control |

| Elongation or Speed Raito | Encoder Calibration |

| Speed Measurement | Speed Balancing |

| Inkjet Print Control | Spool Length |

| Part Length Measurement |

Return on Investment

The Return on Investment (ROI) is often only a few weeks or a few months. The Savings that can be obtained are multi-fold, by:

- Minimize Excess Shipping Length

- Avoid Shipping Shortages

- Avoid product waste

- Eliminate costly maintenance

- Eliminate frequent checks on calibration

- Minimize machine downtime