The brilliant mind of Ilario Properzi invented the Continuous Copper Rod manufacturing system back in the 1960s. Suddenly, the existing and consolidated wire-bar rolling mills became obsolete while other companies strived to copy and replicate this original, successful idea.

However, the reliability and the performance of the Properzi CCR lines remain unparalleled for the production of copper rod whose quality exceeds the ever more stringent demands for fine wire, ultra-fine wire, as well as magnet-wire production in the modern industry.

Moreover, as the best raw materials, unfortunately, do not come at the cheapest price, the Properzi advanced technology facilitates mitigation of the adverse effects that more price appealing cathodes may sometimes have on the final rod quality or productivity.

Continuus-Properzi lines were conceived ahead of their time and continue to provide leading-edge technology.

In fact, our vast experience, consolidated over many years, from numerous lines spread around the globe, allows the Properzi lines to continually evolve and improve, thus enabling the end-users to produce premium-quality wire-rod in a flawless, consistent, and repeatable manner.

A state-of-the-art Properzi CCR line includes, among many others, the following features and devices that are most significant for the rod quality:

Charging equipment designed to optimize the distribution of the cathodes and the permissible scrap inside the melting furnace, to enhance fuel-efficiency, and to extend the refractory lining life while minimizing inclusions.

Vertical melting furnace equipped with the latest high-efficiency Automatic Individual–Combustion Control System to provide consistent metal flow while optimizing oxygen content and temperature of the molten metal stream.

Horizontal holding furnace, specially designed for slag separation and removal.

Fully sealed, atmosphere-controlled transfer launders equipped with slag filtration sections, resulting in cleaner molten copper with controlled, consistent oxygen level.

The tundish design allows fully ceramic metering-pins, thus avoiding inclusion-related wire-breaks due to erosion of the conventional steel metering-pin.

The original, unique Properzi casting machine design allows perfect vertical casting for optimal gas evolution thereby minimizing cast bar porosity.

The special Automatic Sooting Control System enables the generation of a consistent soot layer with an optimal thickness on the casting mold, both wheel and belt, thereby providing a sound, flawless, crack-free cast bar while extending the operational life of these components.

The compact Bar Preparation Unit prevents, by design, any damage to the cast bar, thus avoiding the generation of sub-surface oxides which are detrimental for magnet-wire manufacturing.

The Rolling Mill combines the two-roll configuration and the unique Properzi three-roll technology for optimal material stress distribution during the rolling process, thus enhancing the mechanical properties of the rod while granting it excellent roundness.

The special high-pressure Descaling System efficiently strips off any residual bar surface oxide, thereby preventing it from being rolled in and, again, avoiding problems for magnet-wire manufacturing.

The rolling mill housing design minimizes rolling material oxidation along the advanced lubro-cooling (emulsion) and filtration system.

The design of the Cleaning and Quenching system provides a bright rod with low surface oxides while minimizing the consumption of the reducing agents.

Please note that modern Properzi lines come with the most advanced digital technologies which allow the line itself to operate in fully automatic mode, therefore maintaining the most optimal steady-state operational conditions for extended production runs of consistent rod.

The critical process variables are conveniently stored for future statistical analysis and evaluation thus allowing the further fine-tuning of the settings, as well as maintenance planning.

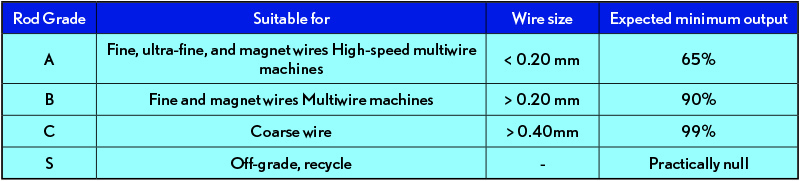

The automatic mode includes rod (coil) grading; as a matter of fact, the real-time evaluation of the critical production variables of each individual coil assures the rod consistency according to standard laboratory tests, therefore significantly increasing the drawing predictability factor.

As far as ultra-fine or magnet wire applications are concerned, every detail of the Properzi line is designed and manufactured with extreme precision and attention. Nonetheless, the line must operate following maximum attention to details and repeatability of the operative procedures and settings. For this purpose, the highly experienced Continuus-Properzi staff supports the CCR end user in the proper operation of the line by selecting raw materials, critical components and consumables, by preparing Standard Operative Procedures and by training the supervisors and operators.

Through the combination of Properzi’s advanced technology, process experience and customer support, it is possible to minimize or avoid rod defects like inclusions, porosities, rolled-in-oxides, as well as all those issues which may affect the rod performance in the most advanced multi-wire, high-speed drawing shops for fine wire or magnet wire.

Providing ordinary A-Grade raw material, a state-of-the-art Properzi CCR line can provide the following average quality output (8mm rod):

Furthermore, if compared to the competition, the design of a Properzi CCR line remains compact and simple. It is easy to operate and even easier to maintain, yet the Properzi design grants extended smooth runs of the premium quality rod on an efficient, consistent, repeatable basis as a result of numerous improvements that have been implemented over time by Continuus-Properzi, the inventor of the Continuous Copper Rod manufacturing system.

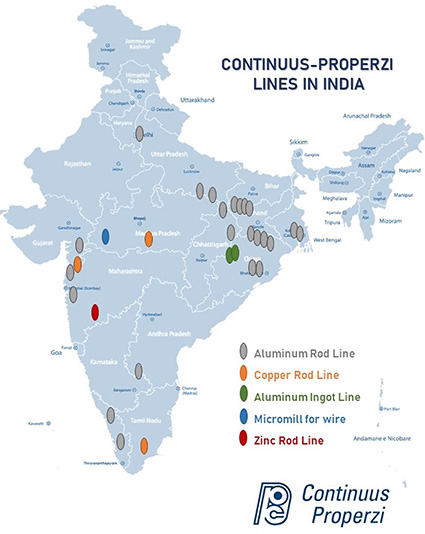

In its 70+ years of activity, Continuus-Properzi has supplied almost 500 plants in all corners of the world in the fields of copper, aluminum, zinc and lead for the production of rod and wire, ingots, and strip. In India, the first supply was in the 1960s, and since then many plants have been installed, as shown on the map, for an actual installed annual capacity of about 250,000 tons of copper rod, 1,000,000 tons of aluminum rod and 200,000 tons of aluminum ingots. All these products are only of Premium Quality – the well-known Properzi quality that is the global benchmark.