“India is HFCL’s home, and the Indian market is the core of our business. Full support of the Indian 5G rollout and BharatNet will be a key part of HFCL’s future growth”, says Dr. Peter A. Weimann, Ph.D., Chief Technology Officer, Optical Fibre Cable, HFCL.

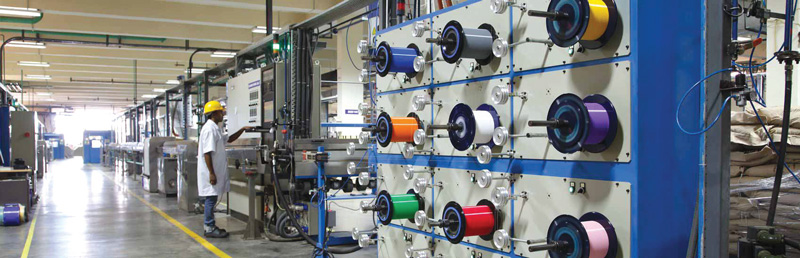

Himachal Futuristic Communications Ltd. (HFCL) is a leading manufacturer of optical fibre cables, optical transport, power electronics, and broadband equipment for the telecommunication industry. With fully integrated world-class manufacturing facilities at five locations across India, HFCL caters to both Indian and global markets. The company is committed to providing cost-effective futuristic end-to-end telecom solutions with a focus on developing state-of-art technologies to maintain sustained long-term growth.

As a part of its strategy to enter new geographies and reach new customers, HFCL keeps on strengthening its leadership team. In an interview with Wire & Cable India, Dr. Peter A. Weimann, Ph.D., Chief Technology Officer, Optical Fibre Cable, HFCL, talks about his new role at the company and capacity expansion plans for the OFC segment.

Wire & Cable India: As you have recently joined HFCL as the Chief Technology Officer, what are you looking forward to in this leadership role? What do you think are the factors driving the growth of HFCL?

Peter A. Weimann: I am excited to help drive HFCL’s growth. We already have a strong and stable base in India, and we will be building on that base to expand our presence in new markets and new geographies.

There are three things that I am especially looking forward to:

• I have always found it rewarding to coach and build teams that are more than the sum of their parts. HFCL’s fibre and cable technology teams are already very effective, but I am looking forward to expanding their size and capability. We will also be increasing our pace of innovation.

• I’m personally motivated by solving problems and getting things done. So, I am looking forward to HFCL working with our customers to develop solutions that help expand network capacity, lower system costs, and speed up network deployment.

• Last but not least, I’m looking forward to widely sharing HFCL’s value proposition with customers around the world. We produce world-class fibre, cable, and connectivity solutions at a large scale, and we’re investing to grow our capability and capacity further. Many people outside India may not know HFCL yet, but they should know us, and I’m excited by the opportunity to teach them.

The biggest factors driving the growth of HFCL are our values and corporate culture. I see three fundamental values driving our decision-making and performance. The first is our responsibility to HFCL employees to ensure the highest levels of safety and provide opportunities for learning, growth, and professional development. The second value is quality. HFCL always goes the extra mile in inspection and testing, to ensure the products leaving our factories are defect-free and meet world-class levels of quality. This is time-consuming and costly, but it’s the right thing to do. The third value is customer service. Every customer order is precious and is treated as such. We strive to deliver products that meet customer expectations on time, every time. We will always do whatever we can to meet customer needs, whether it’s product customisation or investment in new capacity.

HFCL has a strong corporate culture where people live and act according to those values every day. We feel that if we live by those values, everything else we need to be a successful business will follow.

Vertical integration both – backward and forward from our core offering of optical fibre cable brings certainty to our supply chain and allows us to deliver timely, value-added solutions.

Watch: Wire & Cable Industry Year Review

WCI: HFCL has recently announced its plans of taking up its optical fibre capacity to 22 million fkm and optical fibre cable capacity to 34.75 million fkm. Could you please elaborate more on the capacity expansion plans?

PAW: All of the investments will be made in India, with an eye to supporting both domestic and export demand. The fibre and cable market has roared back in the past year after a pause due to both deferred investments by carriers and the COVID-19 pandemic. I’ve recently seen a forecast that the worldwide fibre cable market will grow at a compound annual growth rate greater than 20 percent between now and 2025. The market is there, and we are investing to serve it.

WCI: What strategies have you mapped to boost the business and further amplify the opportunities in the telecom sector?

PAW: One strategy we will continue to pursue is vertical integration. HFCL manufactures many of the inputs for our cables, including optical fibre, fibre-reinforced polymer rods, and fibre glass yarns. We also produce connectorised cables and accessories used during optical cable deployment, including shelves, closures, termination boxes, and fixtures for aerial cables. Vertical integration both – backward and forward from our core offering of optical fibre cable brings certainty to our supply chain and allows us to deliver timely, value-added solutions to our customers.

My joining at HFCL is a part of another key strategy, which is the expansion of HFCL’s sales, marketing, and technical teams outside India in order to grow our presence in new geographies. Our international teams will work with customers worldwide to develop targeted cable and connectivity solutions.

Beyond my personal ‘home’ in the optical fibre & cable business, HFCL’s communications business unit is making significant investments in 5G, WiFi 6, and other wireless technologies. In the future, this will allow HFCL to offer integrated solutions to carriers and enterprises that extend beyond just fibre cable.

WCI: As you hold extensive experience in the optic fibre cable (OFC) sector, in what ways do you think it will reflect in your current role in terms of identifying the technology needs of the sector?

PAW: I have been lucky enough to do a little of everything in my career thus far. I’ve formulated new raw materials, designed novel indoor and FTTH cables, and worked on the evaluation and qualification of new optical fibres. I’ve worked closely with many customers, as well as with many suppliers of raw materials and manufacturing equipment. Through all of that, I have come to appreciate how much I can learn from everyone ranging from machine operators to executives. My approach will be to listen and learn from people inside and outside HFCL and incorporate those inputs into the evolving long-range technology and product strategies for HFCL’s fibre and cable business.

HFCL has diversified its product offering to include products that mostly cater to export markets, including jettable microcables, micromodule cables, and CPR-rated flame-retardant cables. We will continue to broaden our product line with cables, cable assemblies, and apparatus that target the export market.

WCI: What will be your plans with respect to new product introduction, capacity expansion, and process development in strengthening the infrastructure of the telecom and OFC segment?

PAW: One of my favourite quotes is from the late American basketball coach, John Wooden, who instructed his players to “be quick, but don’t hurry.” That’s the philosophy I try to apply to product development, process development, and capacity expansion. It does HFCL’s customers no good if we are late with our solutions. It also does them no good if we provide a rushed solution that is unreliable or low-quality. Balancing the need to be quick with the need to always deliver world-class quality is a difficult challenge, but I am confident HFCL has the team to do this right.

HFCL has diversified its product offering to include products that mostly cater to export markets, including jettable microcables, micromodule cables, and CPR-rated flame-retardant cables. We will continue to broaden our product line with cables, cable assemblies, and apparatus that target the export market. That said, we will not lose sight of the evolving technology needs of the Indian market, especially with the coming of 5G in late 2022 and beyond. For both domestic and export applications, I anticipate that we will increase the rate at which we introduce new products, but we will not release products before they are ready to be manufactured at scale.

Our processes will continue to evolve to support changing technology needs of the market. We design them to be flexible and adaptable, so we can react quickly to emerging market needs.

WCI: What could be the steps that could pave the way for making India a global hub for OFC production and boost the supply chain?

PAW: I think many of those steps have already happened, or are in progress. India certainly has the technical talent and human resources needed to be a global hub for fibre optics. Investments to grow capacity throughout the optical fibre value chain are being made by HFCL and many other companies. Indian companies need to execute on those investments and deliver the fibre and cables the wider world needs.

As you note, boosting the supply chain is a critical piece of making India a global hub for optical fibre cable. The COVID-19 pandemic has resulted in major disruptions in global shipping, including the supply of critical raw materials for optical fibre and cable from outside India. Over time, the Government of India’s ‘Make in India’ programme should result in the increased, cost-effective production of critical raw materials within India.

WCI: Since innovation is regarded to be an important cog in the wheel for any manufacturing company to grow and sustain in the long term, what is your philosophy towards incorporating automation, R&D, and innovation in your business?

PAW: Innovation is often a difficult process in a manufacturing environment. R&D trials, new products, and new processes can give factory general managers big headaches by disrupting standard production. With new optical cable products and processes, you generally can’t fully understand your process capability until you run 50 or 100 cables. Scrap during the production ramp is usually higher than that for established products, and problem-solving during scale-up can occupy a disproportionate share of engineering and quality resources.

However, at HFCL, we understand that in order to best serve our customers, we need to meet those challenges of innovation head-on. Our goal is to provide novel solutions to customer problems that reduce our customers’ total cost of ownership. A quick pace of new innovations delivered with the highest quality is a critical part of our commitment to customer service.

Automation can be a very useful tool in any manufacturing process, but it’s important to keep it in perspective. In order for automation to be effective, it has to help solve specific problems without adding unnecessary complexity to our processes. Our customers don’t buy from us because of the excellence of our automation, they buy from us because we deliver valuable optical fibre and cable solutions for their networks. We’ll invest in automation, but only when it can help us better serve the customer.

Also Read: HFCL Completes Broadband Connectivity in Gram Panchayats in Jharkhand for BharatNet Project

WCI: There’s been a surge in demand for optical fibre cables in view of the national-level projects like BharatNet and the 5G rollout which is projected to boost the OFC market. How do you relate these projections to the prospects of HFCL’s growth?

PAW: In other countries, the rollout of 5G has led to increases in the average fibre count of cables. We expect the same in India, and our investments in new fibre capacity will help HFCL support that when it happens. In contrast, rural broadband schemes generally lead to high demand for low fibre count cables. Our new investments in cable capacity will therefore help HFCL support BharatNet.

All of HFCL’s current manufacturing capacity is in India, and our recently announced expansion will be in India as well. We plan to expand our presence in export markets, but that will not be done at the expense of our support for the Indian market. India is HFCL’s home, and the Indian market is the core of our business. Full support of the Indian 5G rollout and BharatNet will be a key part of HFCL’s future growth.