Pinank Wires and Cables LLP, an ISO 9001:2015 certified company by International Standards Certification and accredited by the joint accreditation system of Germany & Austria, is India’s leading manufacturer of enamelled copper and enamelled aluminum wires. With a current production capacity of 150 TPM, the company has an impressive clientele with big names like Bosch, GE, Cummins and BHEL etc. Their upcoming venture is planned into paper insulated copper conductors (PICC). In a recent interview with Wire & Cable India, Mr. Niren M. Patel, Managing Director, Pinank Wires and Cables LLP, talked about the company’s vision and mission, manufacturing capabilities, clientele and future plans.

“All the manufacturing facilities present in our factory have been developed by the European enameled wire machinery leader – MAG Austria.”

Wire & Cable India: Please share a brief overview of your company.

Niren Patel: Pinank Wires and Cables LLP was established in 2017/2018, and has a current production capacity of 150 TPM. The company is an ISO 9001:2015 certified company by International Standards Certification and accredited by the joint accreditation system of Germany & Austria. We aim to be the most reliable, consistent and innovative provider of winding wire solutions to the electrical industry and to build on our long history and expertise and become one of the largest, high quality, winding wire producers in the world.

Watch: RR Kabel | Solar Cables | Solar Plant | Renewable Energy

WCI: Please shed some light on the company’s manufacturing facility & technology setup.

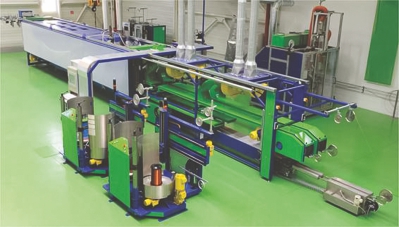

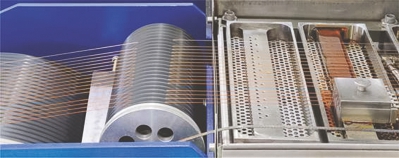

NP: Our factory is situated at Paddhari-Neknam road, Taluka- Tankara .District- Morbi. Neknam, Pin-363650, Gujarat about 700 kms from Mumbai. It is connected to all parts of the country by road & railways and also connected to Mundra & Kandla port of Gujarat which are just 200 kms away. All the manufacturing facilities present in our factory have been developed by the European enameled wire machinery leader – MAG Austria. We have a fully automated plant within a no dust environment, which produces zero error products.

WCI: Brief us about your product portfolio. What is the USP of your products?

NP: Our product portfolio consists of enamelled round winding wires, enamelled rectangular winding wires, super enamelled copper wires, submersible cables, submersible copper winding wires and SWGs with ranges starting from standard wire gauge 6 to 38. The consistent quality of our products, competitive pricing and timely deliveries have helped Pinank Wires & Cables LLP build a wide client base.

WCI: Which markets do your products cater to and what is your clientele?

NP: Our winding wires are used in various applications like transformers, motors, generators, electric appliances, automotives, switchgears etc. Our client base includes discerning multinational corporations like Hindustan Electric Motors, Godrej, General Electric, Bosch, Cummins, BHEL among many others. We have customers in major states of India including Rajasthan, Madhya Pradesh, and the southern states.

“We are aiming to diversify our product portfolio and start manufacturing paper insulated copper conductors (PICC)”

WCI: Are there any upcoming developments or future plans for the company?

NP: Although we are currently focusing on manufacturing enamelled copper wires, we are aiming to diversify our product portfolio and start manufacturing paper insulated copper conductors (PICC). From our end we also want to contribute our products to green energy development, for example to EV manufacturers, in order to support sustainability goals. In the upcoming years, we envision our company becoming major suppliers of enamelled copper wires in the whole world as well as becoming major exporters and domestic players.

Also Read: KENTER’s Success Formula –Sustainable and Quality Products at Economical Prices

WCI: How do you ensure quality improvement and innovation at your organization?

NP: Every batch of wires by Pinank goes through a stringent quality control process that ensures total quality assurance. Our state-of-the-art manufacturing set-up boasts of having a full-fledged laboratory to carry out inspection, testing and quality checks in adherence to the global benchmarks. We go that extra mile to serve our customers better. In fact, we have installed the best available quality testing equipment on line of the manufacturing processes and after every stage of production process, the quality is checked and then the product allowed to go for further operation. After getting the finished product, we are testing the quality of the material 100% on the shop floor.